-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

gi welded mesh manufacturers

The Role of GI Welded Mesh Manufacturers in Modern Construction

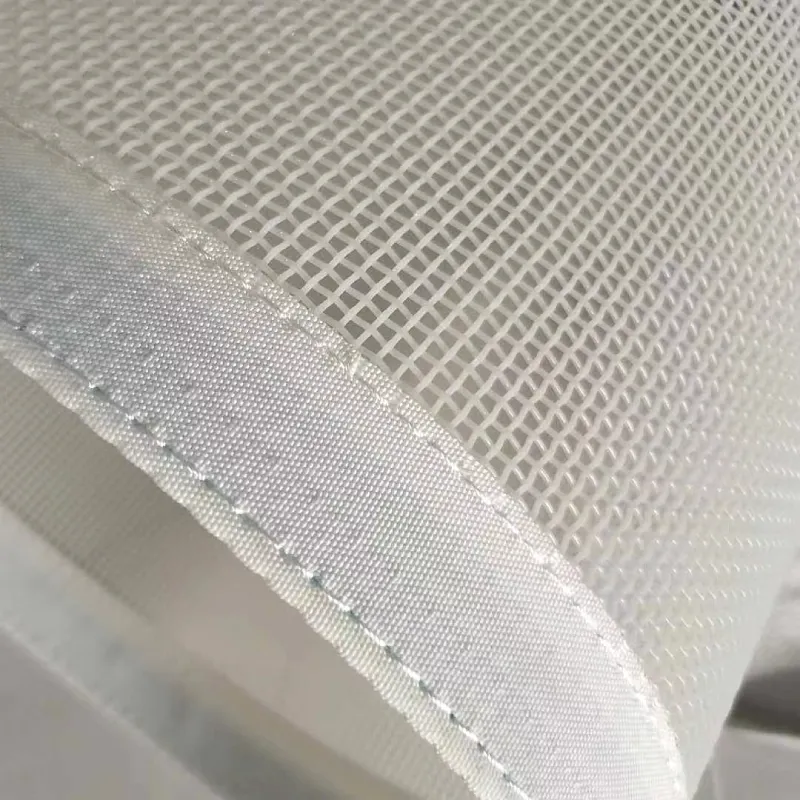

GI (Galvanized Iron) welded mesh is an essential component in the construction industry, known for its durability, strength, and versatility

. Manufacturers of GI welded mesh play a crucial role in providing the necessary materials for various applications, ranging from fencing to reinforcement in concrete structures.GI welded mesh is made from high-quality steel wire that is galvanized to resist corrosion. This process ensures that the mesh can withstand harsh environmental conditions, making it suitable for outdoor use. The mesh is available in various sizes and configurations, allowing it to be adapted for different projects, whether in residential, commercial, or industrial settings.

One of the primary applications of GI welded mesh is in fencing. Manufacturers supply panels that can be used for security fencing around properties, agricultural fields, and construction sites. The durability of galvanized iron ensures that these fences can endure weather changes and potential physical impacts while providing security and visibility.

In addition to fencing, GI welded mesh is extensively used for concrete reinforcement. The mesh acts as a support structure within concrete, increasing its tensile strength and reducing the likelihood of cracking. This is particularly important in the construction of roads, bridges, and buildings, where structural integrity is paramount. By using GI welded mesh, contractors can improve the longevity and stability of their projects.

gi welded mesh manufacturers

Moreover, GI welded mesh is utilized in various landscaping applications. It serves as a framework for garden beds, trellises, and erosion control. Manufacturers offer mesh products that can be easily manipulated to fit specific landscaping designs, allowing for creative and functional outdoor spaces.

The manufacturing process of GI welded mesh involves precise engineering and quality control. Leading manufacturers employ advanced technology to ensure that the mesh is produced with consistent wire gauge and spacing. This attention to detail not only meets industry standards but also maximizes performance and safety for end-users.

In recent years, the demand for GI welded mesh has been rising due to its eco-friendly attributes. The use of galvanized iron allows for better recycling rates at the end of the product's life cycle, contributing to sustainable construction practices.

In conclusion, GI welded mesh manufacturers are pivotal to the construction industry, offering products that enhance safety, durability, and functionality. As the demand for robust construction materials continues to grow, these manufacturers will play an increasingly important role in shaping the future of modern construction. Their commitment to quality and innovation will ensure that GI welded mesh remains a staple in various applications for years to come.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025