-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

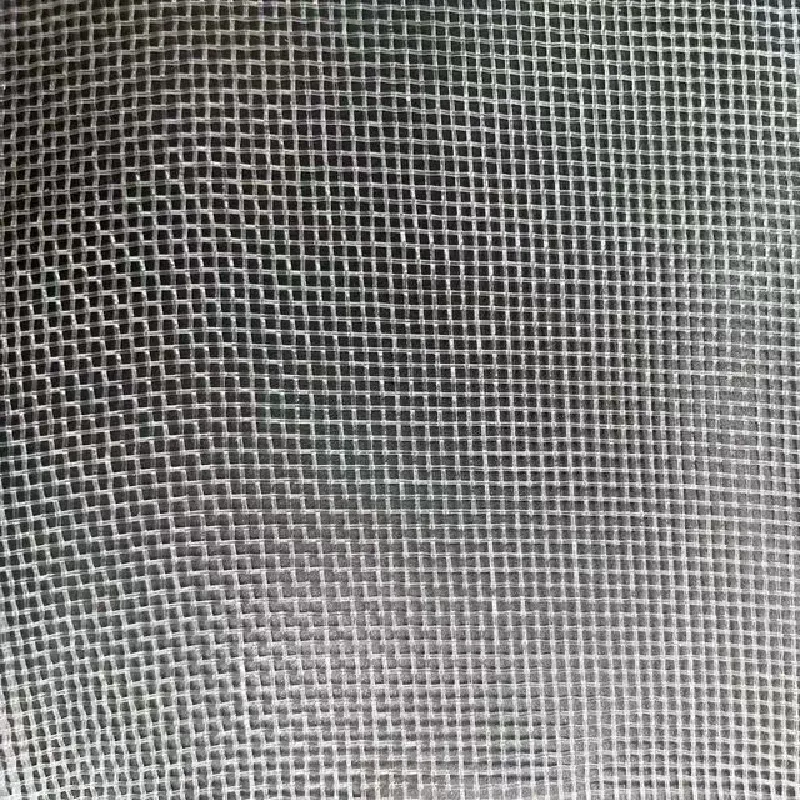

Nylon Mesh Netting Allows Airflow

In the realm of industrial materials and everyday products, few materials offer the blend of versatility, durability, and adaptability found in nylon-based mesh products. From fine filtration in manufacturing to protective netting in agriculture, nylon mesh netting, nylon screen, and nylon mesh material have become indispensable across countless industries. A nylon mesh netting is a woven or knitted structure designed for strength and flexibility, ideal for applications requiring containment or separation. A nylon screen, with its precise pore sizes, excels in filtration and precision separation tasks, ensuring purity in liquids, gases, and solids. Meanwhile, nylon mesh material itself is celebrated for its unique properties—resilience, chemical resistance, and ease of customization—that make it suitable for both industrial rigor and daily use. This article delves into the characteristics, applications, and benefits of these nylon mesh products, highlighting why they remain a top choice for engineers, manufacturers, and everyday users alike.

What is nylon mesh netting and what makes it a versatile material in industrial and daily use?

Nylon mesh netting is a textile material crafted from nylon fibers, woven or knitted into a grid-like structure with uniform openings. Its versatility stems from the inherent properties of nylon, a synthetic polymer known for its strength, elasticity, and resistance to wear and tear. The manufacturing process of nylon mesh netting allows for precise control over mesh size (from large openings for heavy-duty containment to fine weaves for delicate separation), making it adaptable to a wide range of needs.

One key feature of nylon mesh netting is its flexibility. Unlike rigid materials such as metal or plastic sheets, it can be bent, stretched, or shaped without losing structural integrity, making it easy to install in irregular spaces or wrap around objects. This flexibility also contributes to its durability—nylon mesh netting can withstand repeated impacts or vibrations, such as those in industrial machinery or outdoor environments, without tearing or breaking. Additionally, nylon is inherently resistant to moisture, mildew, and many chemicals, ensuring the netting remains functional even in damp or harsh conditions.

In daily use, nylon mesh netting appears in products like window screens, laundry bags, and sports equipment (such as tennis nets or soccer goals), where its lightweight nature and breath ability enhance usability. In industrial settings, it serves as protective barriers in manufacturing plants, cargo containment in logistics, and even as safety netting in construction, proving that its versatility spans from the mundane to the critical.

How does a nylon screen function in filtration and precision separation processes?

A nylon screen is a specialized form of nylon mesh designed with precisely calibrated pore sizes, engineered to separate particles, contaminants, or materials based on size. Its primary function in filtration and separation processes is to act as a physical barrier: when a medium (liquid, gas, or solid mixture) passes through the screen, particles larger than the mesh openings are trapped, while smaller particles or the pure medium flows through. This mechanism ensures consistency, purity, and quality in the end product.

The effectiveness of a nylon screen lies in its uniform mesh structure. Unlike irregular natural materials, nylon can be woven or extruded to create pores of identical size, ensuring reliable and repeatable separation. This precision is critical in industries where even small impurities can compromise results, such as pharmaceuticals, where nylon screen filters remove microscopic contaminants from medicinal solutions, or food processing, where it clarifies juices, syrups, or oils by straining out pulp, seeds, or debris.

In addition to liquid filtration, nylon screen is widely used in dry separation processes. For example, in the plastics industry, it sifts through polymer powders to remove clumps, ensuring uniform mixing during production. In agriculture, it separates seeds by size, guaranteeing consistent planting densities. The screen’s resistance to chemicals and temperature fluctuations further enhances its utility, as it can handle harsh cleaning agents or hot media without degrading. Whether in small-scale laboratory filtration or large industrial pipelines, a nylon screen delivers precision and reliability that few other materials can match.

Key properties of nylon mesh material that enhance its performance across applications

Nylon mesh material owes its widespread use to a unique combination of physical and chemical properties that make it suitable for diverse environments and tasks. These properties, honed through decades of material science innovation, ensure the material performs reliably in everything from heavy industrial use to everyday consumer products. The table below outlines the key properties of nylon mesh material and their practical benefits:

|

Property of Nylon Mesh Material |

Practical Benefit |

|

High tensile strength |

Resists tearing and stretching under heavy loads, making it ideal for containment or structural applications like cargo nets or safety barriers. |

|

Elasticity and flexibility |

Can be bent, folded, or stretched without permanent damage, allowing for easy installation in tight spaces or around irregularly shaped objects. |

|

Moisture resistance |

Does not absorb water, preventing swelling, rotting, or mildew growth—critical for outdoor use (e.g., garden netting) or wet environments (e.g., pool filters). |

|

Chemical resistance |

Withstands exposure to many acids, alkalis, and solvents, ensuring durability in industrial settings where contact with harsh substances is common. |

|

Lightweight construction |

Reduces transportation and installation costs, while making products easier to handle (e.g., lightweight window screens or backpack mesh panels). |

|

Heat resistance (up to moderate temperatures) |

Maintains integrity in warm environments, such as in drying equipment or near industrial heaters, without melting or warping. |

These properties collectively make nylon mesh material a go-to choice for engineers and designers, as it balances performance, durability, and cost-effectiveness across a spectrum of applications.

Practical applications of nylon mesh netting in agriculture, textiles, and everyday life

Nylon mesh netting finds its way into a surprising array of practical applications, thanks to its adaptability and durability. Its uses span industries as varied as agriculture, textiles, and consumer goods, each leveraging specific features of the material to solve unique challenges:

- Agriculture and Horticulture: In farming, nylon mesh nettingis used as crop protection netting, shielding plants from pests (birds, insects) and harsh weather (hail, excessive sunlight) while allowing air, water, and light to penetrate. It also serves as trellis netting for climbing plants like tomatoes or grapes, providing support without damaging stems. Its moisture resistance ensures it lasts through rain and irrigation cycles, reducing the need for frequent replacements.

- Textiles and Apparel: The fashion and textile industry relies on nylon mesh nettingfor its breath ability and stretch. It is used in sportswear, intimate apparel (for comfort and support), and accessories like backpacks or shoes (for lightweight, durable pockets). The material’s elasticity allows for a snug fit that moves with the body, enhancing comfort during activity.

- Everyday Consumer Products: From household items to recreational gear, nylon mesh nettingis a staple. Window and door screens use it to keep insects out while letting fresh air in, thanks to its fine yet durable weave. Laundry bags and toy storage nets utilize its breathable structure to prevent mildew and allow items to dry quickly. In sports, it forms the netting for basketball hoops, badminton courts, and golf practice nets, where its strength withstands repeated impacts.

- Industrial and Commercial Use: Beyond these, nylon mesh nettingserves in industrial settings as conveyor belt screens (for sorting small parts), safety barriers in factories (to prevent accidental contact with machinery), and even as filtration media in water treatment plants (for coarse particle removal). Its versatility ensures it remains a solution for both niche and widespread needs.

FAQS about nylon mesh netting, nylon screen, and nylon mesh material

How durable is nylon mesh netting in outdoor environments?

Nylon mesh netting is highly durable in outdoor environments, thanks to its resistance to moisture, UV radiation, and mildew. While prolonged exposure to intense sunlight can gradually weaken the fibers over several years, most outdoor-grade nylon mesh netting is treated with UV stabilizers to extend its lifespan. With proper care (occasional cleaning to remove debris and avoiding contact with sharp objects), it can last 5–10 years in outdoor settings like gardens, patios, or sports facilities.

What maintenance is required for a nylon screen used in liquid filtration?

A nylon screen used in liquid filtration requires regular cleaning to maintain efficiency. For most applications, rinsing with warm water to dislodge trapped particles is sufficient. For stubborn contaminants (e.g., oils or sticky residues), mild soap or a non-abrasive cleaner can be used. Avoid harsh chemicals that may degrade the nylon fibers. Depending on usage frequency and contamination levels, cleaning should be done weekly to monthly. Inspecting the screen for tears or holes periodically ensures it continues to perform effectively.

How does nylon mesh material differ from polyester mesh in terms of performance?

Nylon mesh material and polyester mesh differ in key performance areas: elasticity, moisture absorption, and heat resistance. Nylon is more elastic, stretching under load and returning to its original shape, making it better for applications requiring flexibility (e.g., sports nets). Polyester has lower elasticity but higher heat resistance, making it suitable for high-temperature environments. Nylon also absorbs slightly more moisture than polyester, though both are considered moisture-resistant. In terms of durability, nylon is stronger under tension, while polyester is more resistant to UV degradation, making it better for long-term outdoor use without UV treatments.

Can nylon screen be customized to specific pore sizes for unique applications?

Yes, nylon screen can be highly customized to specific pore sizes. Manufacturers use precision weaving or extrusion techniques to create screens with openings ranging from micrometers (for fine filtration in laboratories) to several millimeters (for coarse separation in agriculture or mining). Customization also includes mesh thickness, width, and even shape (e.g., circular discs, rectangular sheets, or cylindrical tubes) to fit unique equipment or process requirements. This flexibility makes nylon screen adaptable to virtually any separation or filtration task.

Is nylon mesh netting suitable for contact with food and beverages?

Yes, nylon mesh netting is suitable for contact with food and beverages when made from food-grade nylon. Food-grade nylon mesh netting is manufactured without harmful additives or chemicals, meeting regulatory standards (such as FDA guidelines) for safety in food processing. It is commonly used in applications like straining juices, drying fruits, or containing food items during cooking or storage. Its smooth surface resists bacterial growth, and it can be easily cleaned with food-safe sanitizers, ensuring food safety and quality.

Don’t settle for generic mesh materials that fail to meet your needs. Visit us today to discover how our nylon mesh products can enhance efficiency, reduce costs, and elevate the quality of your work. Your satisfaction is our priority, and we’re ready to help you find the ideal solution. We look forward to welcoming you!

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025