Plastic Nets: Durable, UV-Resistant, Lightweight, Custom

Plastic Flat Nets: what’s changing, what still works, and where buyers are getting real value

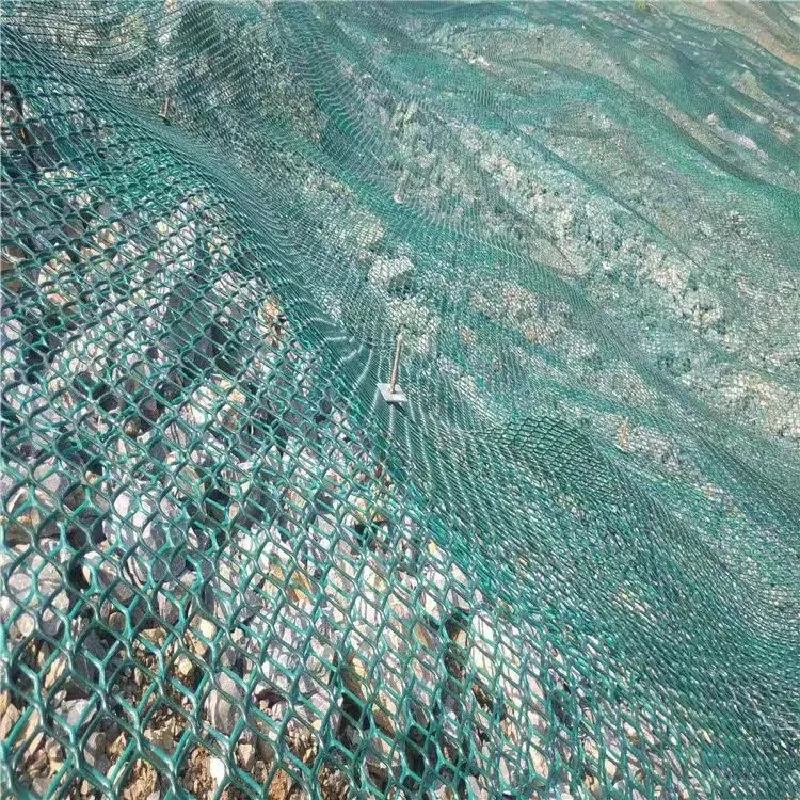

If you’re sourcing Plastic Nets for aquaculture, farming, or light industrial screening, you’ve probably noticed the market getting sharper—more UV-stable resins, tighter mesh tolerances, and, yes, more vendors claiming “factory” status. I’ve been touring plants in coastal China and, to be honest, the best lines still run HDPE and PP through clean extruders with well-kept rotating dies. The product here—Plastic Flat Nets (aka breeding nets)—comes from two molten filaments that meet intermittently as the die rotates, fusing into a stable grid before cooling. Surprisingly elegant, and very repeatable when the screw, die temperature, and haul-off speed are dialed in.

Industry trends I’m seeing

- Shift to UV-stabilized HDPE (HALS packages) for 3–8 years of outdoor life, depending on latitude.

- Mesh consistency getting tighter (aperture deviation ≈ ±0.2–0.4 mm) with better die maintenance.

- Compliance-first buyers asking for REACH/RoHS and food-contact declarations for hatcheries.

- Customization of color (black/green/blue) for algae control or visibility in ponds.

Process flow and quality gates (short version)

Materials: HDPE or PP resin + UV masterbatch → Drying (as needed) → Extrusion (temperature zoning, melt index control) → Rotating die with inner/outer orifices → Twin filament fusion → Water-bath cooling → Haul-off and flattening → Edge trimming → Roll winding → QC. Testing: tensile (ASTM D638/ISO 527), density (ASTM D792), UV aging (ISO 4892-3), chemical resistance (ISO 175), aperture/weight checks. Many customers say the simple thing—consistent roll weight—signals a serious factory.

Typical specifications (real-world use may vary)

| Parameter | Typical range |

|---|---|

| Material | HDPE (primary), PP (optional) |

| Mesh aperture | 2–20 mm ≈, custom up to 60 mm |

| Thickness | 0.6–3.0 mm ≈ |

| Weight | 120–650 g/m² around |

| Tensile strength | ≥ 18–35 MPa (ASTM D638) |

| UV stabilization | HALS, ISO 4892-3 validated |

| Service life | 3–8 years outdoors; indoors 10+ (latitude-dependent) |

| Color | Black/Green/Blue/Custom |

| Roll width/length | 0.5–3.0 m / 30–200 m |

| Origin | China |

Where Plastic Nets earn their keep

- Aquaculture: fish/shrimp breeding cages, nursery partitions, predator exclusion.

- Agriculture: plant support, vineyard protection, poultry runs, compost bin walls.

- Industrial: light screening, air intake pre-filters, packaging separators.

- Construction: facade protection, debris containment (light duty), gutter guards.

Advantages: corrosion-proof, easy to cut/form, buoyant in water, and kinder to fish scales than metal. I guess that’s why hatcheries keep coming back.

Vendor snapshot (what buyers compare)

| Vendor type | Process control | Lead time | Certs | Notes |

|---|---|---|---|---|

| Factory (OEM/ODM) | Die maintenance + resin traceability | 10–25 days ≈ | ISO 9001, SGS, RoHS/REACH | Best for custom mesh/UV packages |

| Trading house | Batch-based QC | 15–35 days | Varies | Flexible sourcing; check consistency |

| Local converter | Cut-to-size, repack | Stock-based | Local | Fast delivery; fewer custom options |

Customization and compliance

Options: aperture, thickness, roll width, colorant, UV package, anti-fouling additives. For food-contact hatcheries, ask for HDPE compliance to FDA 21 CFR 177.1520 and migration data; for the EU crowd, a REACH and RoHS statement is standard. I always request an ISO 4892-3 UV test summary and an ASTM D638 tensile sheet per lot—saves headaches later.

Two quick case notes

1) Shrimp farm, Mekong Delta: swapped metal mesh for Plastic Nets (8 mm aperture, UV black). Reported net damage down 40% and faster cleaning; service life now ≈ 4–5 seasons in tropical sun.

2) Greenhouse, Almería: green 4 mm Plastic Nets for plant support. Less abrasion vs. twine, and workers like the visibility. Minor color fade after 3 summers, but tensile stayed within spec.

What to check before PO

- Mesh tolerance and roll weight per spec sheet.

- UV package details + exposure class (ISO 4892-3 method).

- Tensile and density reports; batch traceability.

- Regulatory declarations (FDA/REACH/RoHS) if relevant.

References

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025