-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Safety Netting Requires Regular Inspection

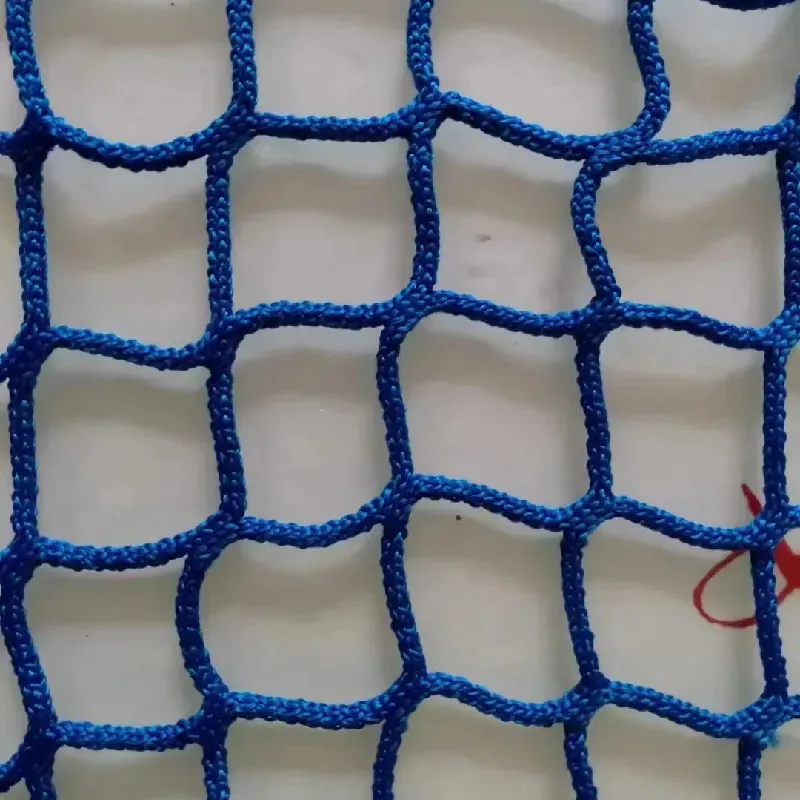

In the construction industry, safety is paramount, and few tools are as critical to protecting workers as scaffold netting, safety netting, and proper safety netting construction. These specialized products form a vital line of defense against falls, debris, and hazards, ensuring worksites remain secure and compliant with industry standards. From high-rise buildings to small renovation projects, they combine durability, functionality, and reliability to safeguard lives and enhance efficiency. In this guide, we’ll explore their features, applications, and best practices, drawing on insights from trusted industry resources to highlight their importance in construction safety.

The Vital Role of Scaffold Netting in Construction Site Safety

Scaffold netting is a cornerstone of construction site safety, designed to protect workers, contain debris, and maintain a secure environment around scaffolding structures. Crafted primarily from high-density polyethylene (HDPE), scaffold netting is engineered to withstand the rigors of construction, including UV exposure, wind, and physical impact—qualities that make it indispensable for elevated work zones.

One of the primary functions of scaffold netting is fall protection, acting as a barrier to prevent workers or tools from slipping off scaffolding. Its tightly woven mesh also contains debris, such as bricks, nails, or dust, preventing them from falling to lower levels and endangering pedestrians or workers below. Unlike traditional materials, scaffold netting is lightweight yet strong, allowing for easy installation on scaffolding frames while maintaining structural integrity. Additionally, it provides partial wind protection, reducing the risk of workers losing balance in gusty conditions—making it a versatile tool that enhances overall worksite safety.

How Safety Netting Safeguards Workers Across All Construction Environments

Safety netting serves as a universal safety solution, protecting workers in diverse construction settings from high-rise buildings to bridge renovations. Beyond fall prevention, it creates a protective buffer that minimizes risks associated with elevated work, making it a non-negotiable component of modern construction safety protocols.

Safety netting is designed to absorb impact, reducing the force of falls and preventing serious injury.When properly installed, it acts as a secondary safety system, complementing harnesses and guardrails to create multiple layers of protection. Made from UV-resistant, high-strength materials like HDPE, safety netting resists tearing, rotting, and degradation, ensuring long-term performance even in harsh weather conditions. Its flexibility allows it to conform to different structures, from scaffolding to building exteriors, while its porous design permits airflow—reducing wind resistance that could destabilize worksites. For construction teams, safety netting isn’t just a regulatory requirement; it’s a lifeline that fosters confidence and productivity.

The Importance of Proper Safety Netting Construction for Compliance and Reliability

Effective safety netting isn’t just about the product itself—it’s about how it’s installed, and safety netting construction refers to the careful planning, installation, and inspection that ensure the netting performs as intended. Proper safety netting construction is critical for meeting regulatory standards, preventing failures, and maximizing worker protection.

Safety netting construction begins with thorough site assessment, identifying high-risk areas like unprotected edges, open floors, or scaffolding gaps that require netting coverage.** Installation teams then select the appropriate netting type based on the site’s needs—whether lightweight mesh for debris containment or heavy-duty netting for fall arrest. Proper anchoring is key: nets must be securely attached to stable structures using reinforced edges and durable fasteners to withstand impact forces. Post-installation, inspections are conducted to check for tension, gaps, or damage, ensuring the netting meets industry standards. By prioritizing meticulous safety netting construction, worksites reduce liability, avoid accidents, and demonstrate a commitment to worker well-being.

Key Features to Prioritize in High-Quality Scaffold Netting

Not all scaffold netting products offer the same level of protection, and selecting the right one depends on understanding its core features. High-quality scaffold netting is engineered to balance strength, durability, and functionality, ensuring it meets the demands of construction environments. Below is a breakdown of essential features:

|

Feature |

Description |

Benefit for Construction Sites |

|

Material |

High-density polyethylene (HDPE) with UV stabilizers. |

Resists sun damage, tearing, and rot, ensuring long-term durability. |

|

Mesh Size |

Uniform, small to medium mesh to contain debris and prevent falls. |

Blocks tools/debris from falling while allowing airflow to reduce wind stress. |

|

Edge Reinforcement |

Double-stitched or reinforced borders with grommets for secure anchoring. |

Prevents tearing at attachment points, maintaining structural integrity. |

|

Tensile Strength |

Designed to absorb impact from falls or heavy debris. |

Reduces injury risk by cushioning falls and containing heavy objects. |

These features ensure scaffold netting not only meets safety regulations but also withstands the daily rigors of construction, from heavy equipment vibrations to exposure to dust and moisture. Investing in high-quality scaffold netting reduces replacement costs and ensures consistent protection throughout a project’s lifecycle.

FAQS about Scaffold Netting, Safety Netting, and Safety Netting Construction

What materials make scaffold netting durable enough for construction sites?

Scaffold netting is primarily made from high-density polyethylene (HDPE), a material valued for its exceptional strength, flexibility, and resistance to UV rays, moisture, and impact. Many variants include UV stabilizers during manufacturing to prevent degradation from prolonged sun exposure, while reinforced edges (often with polypropylene binding) enhance durability at attachment points. This combination ensures scaffold netting withstands the harsh conditions of construction sites, from wind and rain to physical stress.

How does safety netting prevent falls in elevated construction work?

Safety netting prevents falls through a combination of impact absorption and barrier protection. When a worker or object falls, the net’s tightly woven mesh catches and distributes the force across its surface, reducing the impact to safe levels. Installed below work areas or around unprotected edges, it creates a physical barrier that stops falls before they result in injury. Its flexibility allows it to stretch slightly upon impact, further cushioning the fall, while secure anchoring ensures the net doesn’t dislodge—making it a critical secondary safety system.

What standards guide proper safety netting construction for regulatory compliance?

Safety netting construction is governed by industry standards that ensure consistency and reliability. These standards specify requirements for mesh size, tensile strength, anchoring methods, and installation spacing to maximize protection. Compliance with these guidelines—such as ensuring nets are installed close enough to work areas to catch falls quickly and anchored to stable structures—ensures worksites meet legal requirements and minimize accident risks.

Can scaffold netting be reused across multiple construction projects?

Yes, scaffold netting can be reused if properly maintained and inspected. After each project, the netting should be cleaned to remove debris, checked for tears, fraying, or weakened edges, and repaired if necessary. UV-resistant materials ensure it retains strength over multiple uses, though lifespan depends on exposure to harsh conditions. Reusing well-maintained scaffold netting reduces waste and costs while maintaining safety—a sustainable choice for construction teams.

How often should safety netting be inspected after safety netting construction?

After safety netting construction, inspections should be conducted regularly to ensure ongoing reliability. Industry guidelines recommend inspections before each work shift to check for visible damage, loose anchors, or gaps. More thorough inspections are needed after severe weather, heavy impact (e.g., a fallen tool), or modifications to the worksite. Prompt repairs or replacements of damaged sections ensure the safety netting continues to provide effective protection, keeping workers safe throughout the project.

At [Anping County Yongji Metal Products Co., Ltd.], we’re dedicated to prioritizing construction safety with high-quality scaffold netting, safety netting, and expert guidance on safety netting construction. Our products are crafted from premium HDPE with UV resistance, reinforced edges, and rigorous testing to meet industry standards, ensuring they protect workers and enhance worksite compliance.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025