-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

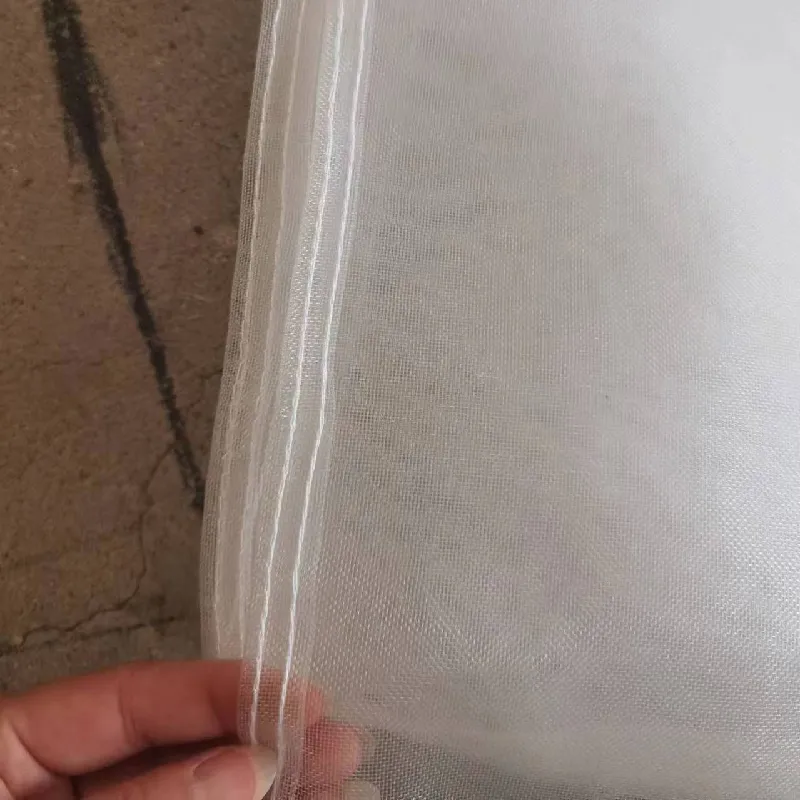

stainless steel filtration mesh

Understanding Stainless Steel Filtration Mesh A Versatile Solution for Various Industries

Stainless steel filtration mesh is an essential component in many industrial applications, prized for its durability, resistance to corrosion, and versatility. This type of mesh is designed to separate solids from liquids or gases, making it crucial in processes ranging from water treatment to pharmaceuticals and food production. In this article, we will delve into the various advantages of stainless steel filtration mesh, its applications, and the factors to consider when selecting the right mesh for specific needs.

Advantages of Stainless Steel Filtration Mesh

1. Corrosion Resistance One of the primary benefits of stainless steel is its inherent resistance to corrosion. This property ensures that filtration systems can operate effectively in moist or chemically aggressive environments. Unlike other materials, stainless steel maintains its structural integrity and performance over time, making it a reliable choice for industries that require rigorous hygiene and sanitation standards.

2. Strength and Durability Stainless steel filtration mesh is built to withstand high pressures and flows. Its robust construction allows it to endure harsh working conditions, including extreme temperatures and physical stress. This durability translates to longer service life and reduced replacement costs, providing a great return on investment.

3. Versatility Stainless steel filtration mesh comes in various sizes and mesh configurations, allowing for customized filtration solutions. It can effectively filter different substances, whether they are fine particles in liquids or chips and debris in gases. Its versatility extends to various applications, from industrial processes, automotive manufacturing, and chemical processing to home filtration systems.

4. Hygienic and Non-Toxic In industries such as food and beverage, pharmaceuticals, and cosmetics, hygiene is of paramount importance. Stainless steel is non-toxic and easy to clean, ensuring that it does not contaminate the materials being filtered. Its smooth surface and resistance to bacteria growth further enhance its suitability for these sensitive applications.

5. Cost-Effectiveness While the initial investment in stainless steel filtration mesh may be higher than that of other materials, its long-term savings outweigh the upfront costs. The durability means less frequent replacements, and its low maintenance requirements contribute to lower overall operational costs.

Applications of Stainless Steel Filtration Mesh

The applications of stainless steel filtration mesh are vast and varied. Some of the most prominent include

- Water Treatment In water treatment plants, stainless steel mesh is used to filter out contaminants, ensuring clean and safe drinking water. Its ability to handle high flows and fine particulates makes it ideal for this essential application.

stainless steel filtration mesh

- Food and Beverage Industry Stainless steel mesh is widely used in the food industry for applications such as brewing, juice production, and dairy processing. It helps maintain product quality by providing effective filtration while complying with strict hygiene regulations.

- Chemical Processing In the chemical industry, stainless steel filtration mesh is employed to separate catalysts, solids, and other impurities from liquids and gases, contributing to cleaner production processes

.- Pharmaceuticals The pharmaceutical sector relies on stainless steel mesh for its robustness and hygienic properties, playing a vital role in the production of medicines and other health products.

- Oil and Gas In the oil and gas industry, filtration mesh is utilized to remove solids from crude oil and gas streams, ensuring efficient processing and protecting equipment from damage.

Choosing the Right Stainless Steel Filtration Mesh

When selecting the appropriate stainless steel filtration mesh, several factors should be considered

1. Mesh Size The opening size of the mesh will directly affect the filtration efficiency and the types of particles that can be captured.

2. Wire Diameter The thickness of the wires affects the strength and durability of the mesh.

3. Material Grade Different grades of stainless steel are suitable for different environments, and it’s essential to choose the correct one based on the specific application.

4. Flow Rate Understanding the required flow rate will help in selecting a mesh that can handle the intended volume without causing significant pressure loss.

In conclusion, stainless steel filtration mesh is an indispensable tool across various industries, providing effective filtration solutions while ensuring durability and hygiene. By understanding its properties and applications, businesses can make informed decisions that enhance their operational efficiency and product quality.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025