-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

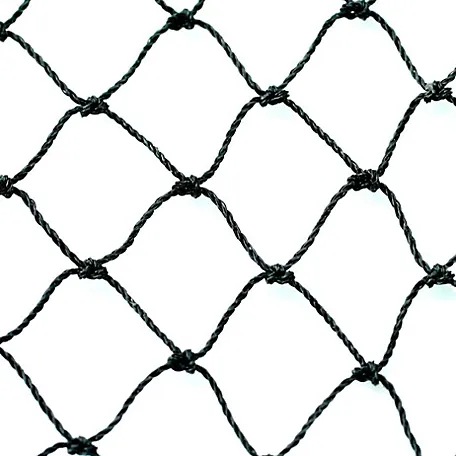

Stainless Steel Knitted Wire Mesh for Versatile Applications and Enhanced Durability

The Versatility of Stainless Steel Knitted Wire Mesh

Stainless steel knitted wire mesh is a remarkable material that has found applications in various industries due to its unique properties, exceptional strength, and versatility. Made from premium quality stainless steel, this type of mesh consists of interconnected wires that are woven together in a specific pattern, creating a fabric-like network. This innovative mesh is not only durable but also resistant to corrosion, making it an ideal choice for numerous applications.

Properties of Stainless Steel Knitted Wire Mesh

One of the standout features of stainless steel knitted wire mesh is its remarkable strength. The interlocking formation of the wires gives it a high tensile strength, allowing it to withstand significant stress and strain without breaking. This strength is particularly crucial in industries like construction and manufacturing, where the integrity of materials is paramount.

Another key characteristic of this mesh is its resistance to corrosion. Stainless steel is naturally resistant to rust and oxidation due to the presence of chromium, which forms a thin layer of oxide on the surface. This property makes stainless steel knitted wire mesh suitable for outdoor applications and in environments where moisture and chemicals are prevalent.

The lightweight nature of knitted wire mesh is yet another advantage. Despite its strength, the overall weight is significantly lower than that of solid materials, making it easier to handle and install. This lightweight quality is especially valued in applications where weight constraints are a concern, such as in aerospace and automotive industries.

Moreover, the versatility of stainless steel knitted wire mesh allows it to be customized in various weaves, sizes, and thicknesses to meet specific requirements. The mesh can be produced in roll form, sheets, or cut to size, making it adaptable for different projects.

Applications of Stainless Steel Knitted Wire Mesh

Stainless steel knitted wire mesh has a wide range of applications across multiple sectors

stainless steel knitted wire mesh

1. Filtration One of the primary uses of this mesh is in filtration systems. Its fine yet permeable structure allows for effective separation of solids from liquids or gases. It is commonly used in water filtration, food processing, pharmaceutical industries, and petrochemical applications.

2. Architectural Design The aesthetic appeal of stainless steel knitted wire mesh makes it popular in architectural applications. Designers and architects utilize it for facades, railings, and decorative elements, combining functionality with modern aesthetics.

3. Industrial Uses In manufacturing and industrial settings, knitted wire mesh serves as a protective barrier, safety guard, or support. It can be applied in machinery, equipment, and as part of conveyor systems to prevent debris from causing damage.

4. Medical Applications In the medical field, stainless steel knitted wire mesh finds its place in surgical instruments and medical devices. Its biocompatibility and ease of sterilization make it suitable for various healthcare applications.

5. Automotive Industry In the automotive sector, stainless steel knitted wire mesh is used in air and fuel filtration systems, ensuring that impurities do not enter engines, thereby safeguarding performance and longevity.

6. Food Industry The food industry also benefits from this material, where the mesh is employed in processes such as sieving and separation, ensuring the integrity of food products. Its resistance to corrosion and ease of cleaning make it ideal for food processing applications.

Conclusion

Stainless steel knitted wire mesh stands out as a highly versatile and durable material suitable for a plethora of applications. Its unique combination of strength, resistance to corrosion, lightweight properties, and adaptability makes it a preferred choice across different industries. Whether in industrial settings, architectural design, or medical equipment, the utility of stainless steel knitted wire mesh continues to expand, showcasing its remarkable potential. As technology advances and new applications are explored, the demand for this exceptional material is likely to grow, solidifying its place in innovative solutions for modern-day challenges.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025