-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

stainless steel mesh manufacturers

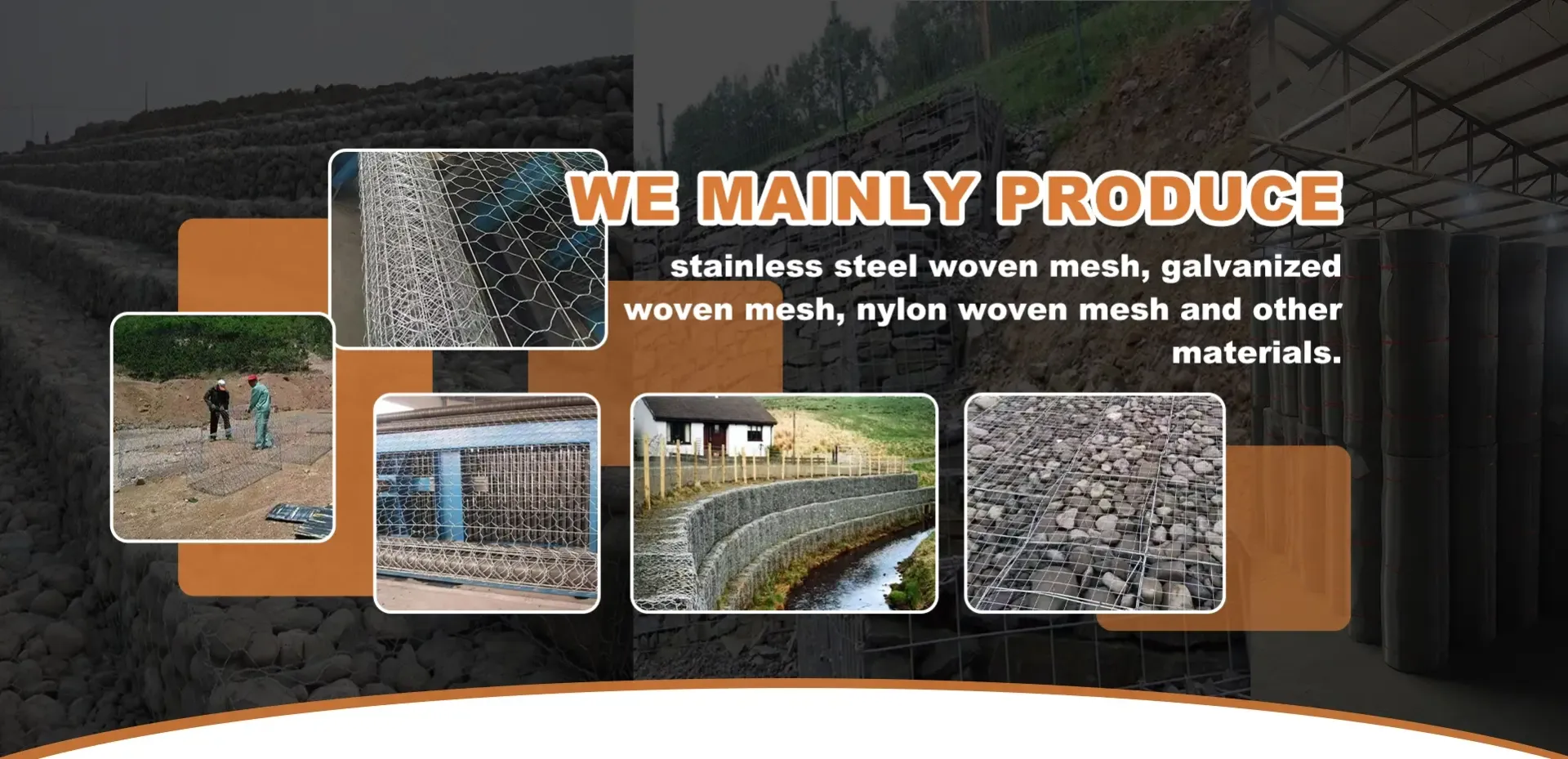

Understanding Stainless Steel Mesh Manufacturers A Comprehensive Overview

Stainless steel mesh is an essential material in various industries, known for its durability, corrosion resistance, and versatility. It is widely used in applications ranging from construction and filtration to agriculture and architecture. As the demand for stainless steel mesh continues to rise, numerous manufacturers have emerged globally, each offering different products tailored to specific needs. This article delves into the vital aspects of stainless steel mesh manufacturers, outlining their significance, production processes, and considerations for selecting a reputable supplier.

The Importance of Stainless Steel Mesh

Stainless steel mesh is favored for its robustness and resistance to environmental factors, making it ideal for demanding applications. Its unique properties enable it to maintain integrity in high temperatures and corrosive environments. Industries such as food processing, pharmaceuticals, and water treatment often rely on stainless steel mesh for its hygienic properties and ease of cleaning, ensuring that safety and quality standards are met.

Types of Stainless Steel Mesh

Manufacturers produce various types of stainless steel mesh, catering to different applications. The most common types include

1. Woven Wire Mesh This is made by interweaving stainless steel wires, creating a sturdy and flexible material. It is often used in filtration systems, screen applications, and architectural projects.

2. Expanded Metal Mesh Created by slitting and stretching a flat sheet of stainless steel, expanded metal mesh features a diamond pattern that offers strength and ventilation. It is ideal for walkways, security fencing, and decorative elements.

3. Perforated Metal Mesh This type is produced by punching holes into flat sheets of stainless steel. It is commonly used in soundproofing, air filtration, and as an aesthetic design feature.

4. Stainless Steel Wire Cloth This is a finer mesh option often used for filtering applications where precision is critical, such as in laboratories or high-purity environments.

Key Manufacturing Processes

The production of stainless steel mesh involves several critical steps to ensure the finished product meets industry standards

. These steps typically include1. Material Selection Stainless steel comes in various grades, with 304 and 316 being the most common for mesh applications. Manufacturers select the appropriate grade based on the intended use, particularly considering factors like corrosion resistance and strength.

stainless steel mesh manufacturers

2. Wiring Process For woven wire mesh, the manufacturing process involves weaving stainless steel wires using machinery designed for precision. The width, gauge, and weave pattern can vary to produce different mesh specifications.

3. Surface Treatment To enhance durability and aesthetics, stainless steel mesh may undergo surface treatments such as pickling, passivation, or powder coating. These processes can improve corrosion resistance and ensure ease of maintenance.

4. Quality Control Reputable manufacturers implement stringent quality control measures to guarantee that every batch of stainless steel mesh adheres to industry specifications. This often includes testing for tensile strength, mesh opening size, and resistance to corrosion.

Considerations for Choosing a Manufacturer

When selecting a stainless steel mesh manufacturer, several factors should be taken into account

1. Experience and Reputation Opt for manufacturers with a proven track record in the industry. An experienced company is likely to deliver higher quality products and more reliable service.

2. Product Range A manufacturer offering a wide variety of mesh types may better meet your specific requirements, whether for industrial use or construction projects.

3. Customization Options The ability to customize specifications, such as mesh size, wire gauge, and finish, can significantly enhance the suitability of the product for your specific application.

4. Certifications and Standards Ensure the manufacturer complies with relevant industry standards and holds necessary certifications, as this can be indicative of product quality and safety.

5. Customer Support Reliable customer service is essential for addressing queries, providing product information, and facilitating a smooth purchasing process.

Conclusion

Stainless steel mesh manufacturers play a crucial role in supplying essential materials needed across various industries. By understanding the different types of meshes, manufacturing processes, and key considerations when selecting a supplier, businesses can make informed decisions that lead to successful outcomes. As industries evolve and expand, stainless steel mesh will continue to be a vital component, supporting innovation and quality in diverse applications. Whether it's for filtration, construction, or aesthetic purposes, the significance of choosing the right manufacturer cannot be overstated.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025