-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

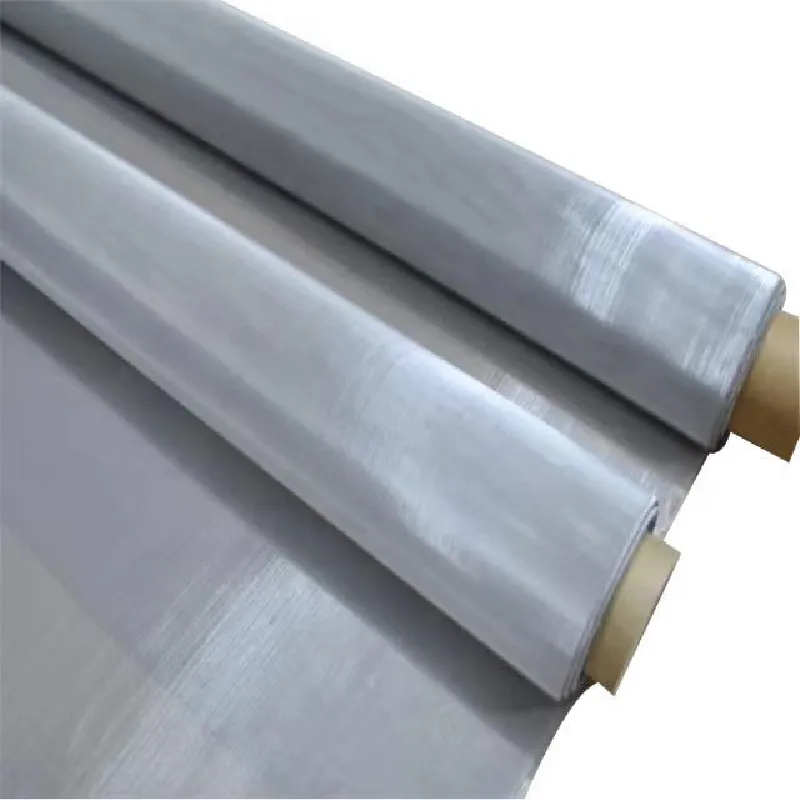

Durable Stainless Steel Woven Mesh for Versatile Applications and Long-lasting Performance

The Versatility of Stainless Steel Woven Mesh

Stainless steel woven mesh is a remarkable material that has gained widespread popularity across various industries due to its exceptional properties and versatility. It is made from high-quality stainless steel fibers that are interwoven to create a durable and resilient mesh structure. This article explores the characteristics, uses, and benefits of stainless steel woven mesh, showcasing why it is an essential material in modern applications.

Characteristics of Stainless Steel Woven Mesh

One of the most significant advantages of stainless steel woven mesh is its resistance to corrosion. Unlike other materials, stainless steel maintains its integrity when exposed to moisture, chemicals, and extreme weather conditions. This makes it ideal for applications in harsh environments, such as chemical processing plants, marine industries, and outdoor installations.

In addition to its corrosion resistance, the mesh is known for its high tensile strength. This characteristic allows it to bear heavy loads without deforming or breaking, making it suitable for applications that require structural stability. Furthermore, stainless steel woven mesh can be easily fabricated into various sizes and shapes, allowing for customization to meet specific project needs.

Another remarkable property of stainless steel woven mesh is its aesthetic appeal. The sleek and shiny appearance of stainless steel adds a modern touch to architectural projects. It is often used in building facades, balustrades, and decorative applications, enhancing the overall aesthetic while providing functional benefits.

Applications of Stainless Steel Woven Mesh

stainless steel woven mesh

Stainless steel woven mesh finds applications in a diverse range of sectors. In the construction industry, it is commonly used for reinforcing concrete and as a protective barrier in various structural applications. Its strength and durability make it an excellent choice for maintaining the integrity of buildings and other infrastructure.

In the food and beverage industry, stainless steel woven mesh plays a crucial role in filtration processes. It is used in various filtration systems to separate solids from liquids, ensuring product quality and safety. Its non-reactive nature makes it suitable for use in food processing and handling, adhering to stringent hygiene standards.

Another significant application of stainless steel woven mesh is in the automotive industry. It is utilized in the manufacturing of filters for air, oil, and fuel, contributing to the overall efficiency and reliability of vehicles. Additionally, stainless steel woven mesh is used in exhaust systems, where high temperatures and corrosive gases are present.

Benefits of Using Stainless Steel Woven Mesh

The benefits of using stainless steel woven mesh extend beyond its physical properties. Its longevity and low maintenance requirements translate to cost savings over time. Unlike other materials that may need frequent replacements, stainless steel woven mesh can endure years of use, providing a reliable solution for various applications.

Moreover, its recyclability makes stainless steel an environmentally friendly option. As industries become increasingly conscious of sustainability, using materials that can be recycled and reused has become a priority. Stainless steel woven mesh can be repurposed at the end of its life cycle, reducing waste and promoting a circular economy.

In conclusion, stainless steel woven mesh is a versatile and invaluable material with extensive applications across multiple industries. Its unique combination of corrosion resistance, high tensile strength, and aesthetic appeal makes it suitable for various uses, from construction to food processing and automotive manufacturing. As technology and innovation continue to evolve, the demand for stainless steel woven mesh is expected to grow, solidifying its position as a cornerstone material in modern manufacturing and design.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025