-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Stainless Steel Suction Strainer for Efficient Liquid Filtration and Protection

Understanding Stainless Steel Suction Strainers Importance and Applications

Stainless steel suction strainers are crucial components in various industrial applications, ensuring the efficient operation of fluid systems. These devices are designed to filter out debris and particles from liquids before they enter pumps or other equipment, protecting them from potential damage and ensuring optimal performance.

Understanding Stainless Steel Suction Strainers Importance and Applications

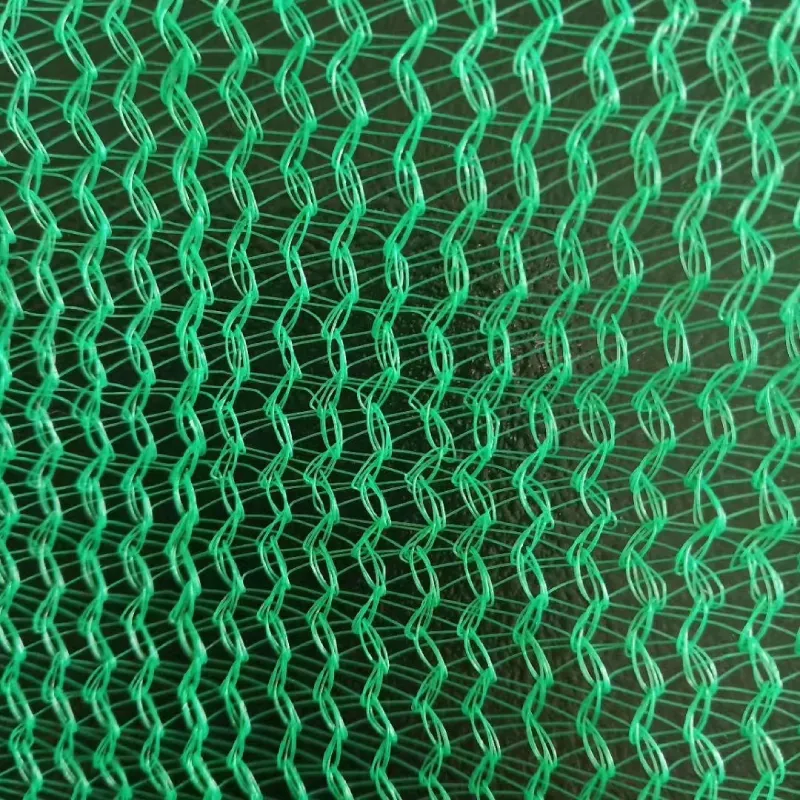

The design of suction strainers is equally important. They typically consist of a mesh or perforated screen that captures particles while allowing liquids to flow freely. The size of the openings in the strainer’s mesh is critical; they must be small enough to catch undesirable debris but large enough to prevent excessive restriction of flow. This balance is essential for maintaining the efficiency of the entire system. Common mesh sizes range from 20 to 200 microns, allowing for customization based on specific application requirements.

stainless suction strainer

Installation and positioning of these strainers are also vital considerations. They should be strategically located in the system to ensure that all incoming fluid passes through the strainer. Regular maintenance, such as cleaning or replacing the strainer when necessary, is essential to maintain flow rates and system efficiency. Neglecting to do so can lead to clogs and ultimately system failure.

The applications of stainless steel suction strainers are diverse. They are widely used in industries such as water treatment, where they prevent sand and other particulates from damaging pumps and valves. In the food and beverage sector, they help maintain product quality by ensuring that the liquids are free from contaminants. Furthermore, in the oil and gas industry, these strainers protect critical infrastructure by filtering out particles that could lead to equipment damage.

In conclusion, stainless steel suction strainers play a pivotal role in protecting industrial systems from contaminants. Their durability, efficient design, and versatility make them indispensable in various applications. Investing in high-quality suction strainers is not just a matter of efficiency; it is a critical step in ensuring the longevity and reliability of fluid systems across multiple industries.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025