-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 06, 2025 11:45

Back to list

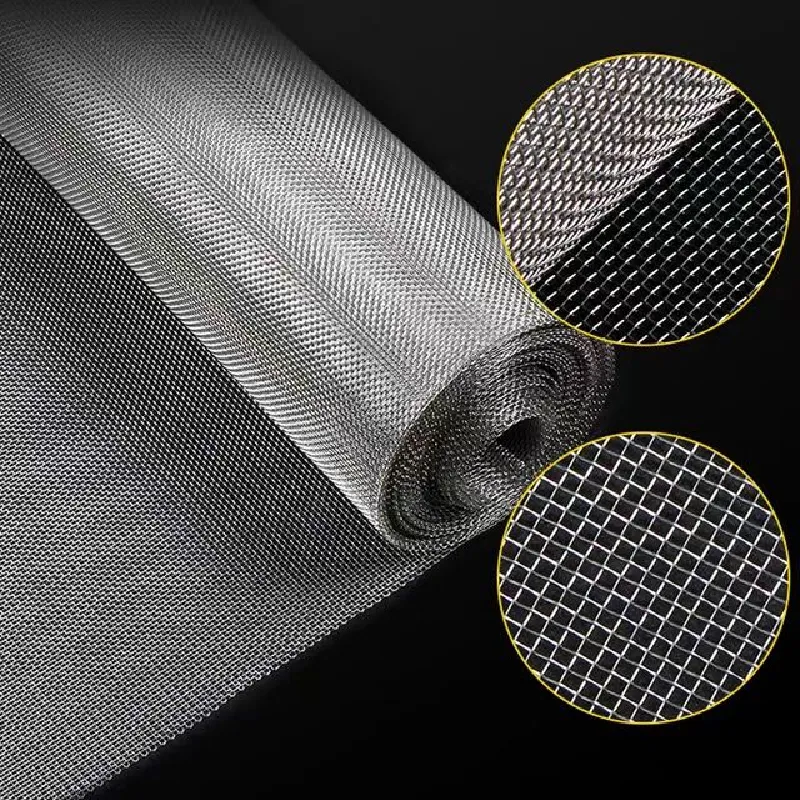

stainless woven wire mesh

Stainless woven wire mesh, a versatile and valued product, plays a crucial role across a myriad of industries, offering both practicality and reliability. Its design, combining durability with aesthetic appeal, makes it an essential component in various applications ranging from industrial to architectural uses. This article explores the multifaceted uses of stainless woven wire mesh, drawing on years of professional experience and industry knowledge.

Innovation continues to drive the evolution of stainless woven wire mesh. Recent advances have seen enhancements in weaving techniques, leading to the development of multi-layered meshes that offer augmented strength and filtration capacity. These newer versions cater to specialized applications, such as pharmaceutical manufacturing or high-precision laboratory settings, where even minor deviations can have substantial repercussions. Drawing on an authoritative perspective, as a seasoned professional, I advise comprehensive consultation with manufacturers or suppliers when selecting the right type of stainless woven wire mesh. They provide insights derived from extensive field knowledge and can offer tailored solutions that align with specific project requirements, ensuring optimal performance and cost-efficiency. Trust is further cemented through transparency and open communication between supplier and client, where understanding client needs translates into innovative product recommendations and applications. This collaborative approach has been instrumental in many successful implementations of stainless woven wire mesh in demanding environments. In conclusion, stainless woven wire mesh, with its blend of strength, flexibility, and aesthetic appeal, establishes itself as a product of choice across diverse fields. Its success is not merely rooted in its physical properties but also in the confidence and quality assurance it delivers. Trust, expertise, and a commitment to excellence are foundational pillars that ensure stainless woven wire mesh remains indispensable in both industrial and architectural domains. Business leaders and engineers alike recognize that leveraging this material can significantly enhance operational success, solidifying its role as a cornerstone in materials engineering.

Innovation continues to drive the evolution of stainless woven wire mesh. Recent advances have seen enhancements in weaving techniques, leading to the development of multi-layered meshes that offer augmented strength and filtration capacity. These newer versions cater to specialized applications, such as pharmaceutical manufacturing or high-precision laboratory settings, where even minor deviations can have substantial repercussions. Drawing on an authoritative perspective, as a seasoned professional, I advise comprehensive consultation with manufacturers or suppliers when selecting the right type of stainless woven wire mesh. They provide insights derived from extensive field knowledge and can offer tailored solutions that align with specific project requirements, ensuring optimal performance and cost-efficiency. Trust is further cemented through transparency and open communication between supplier and client, where understanding client needs translates into innovative product recommendations and applications. This collaborative approach has been instrumental in many successful implementations of stainless woven wire mesh in demanding environments. In conclusion, stainless woven wire mesh, with its blend of strength, flexibility, and aesthetic appeal, establishes itself as a product of choice across diverse fields. Its success is not merely rooted in its physical properties but also in the confidence and quality assurance it delivers. Trust, expertise, and a commitment to excellence are foundational pillars that ensure stainless woven wire mesh remains indispensable in both industrial and architectural domains. Business leaders and engineers alike recognize that leveraging this material can significantly enhance operational success, solidifying its role as a cornerstone in materials engineering.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025