-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

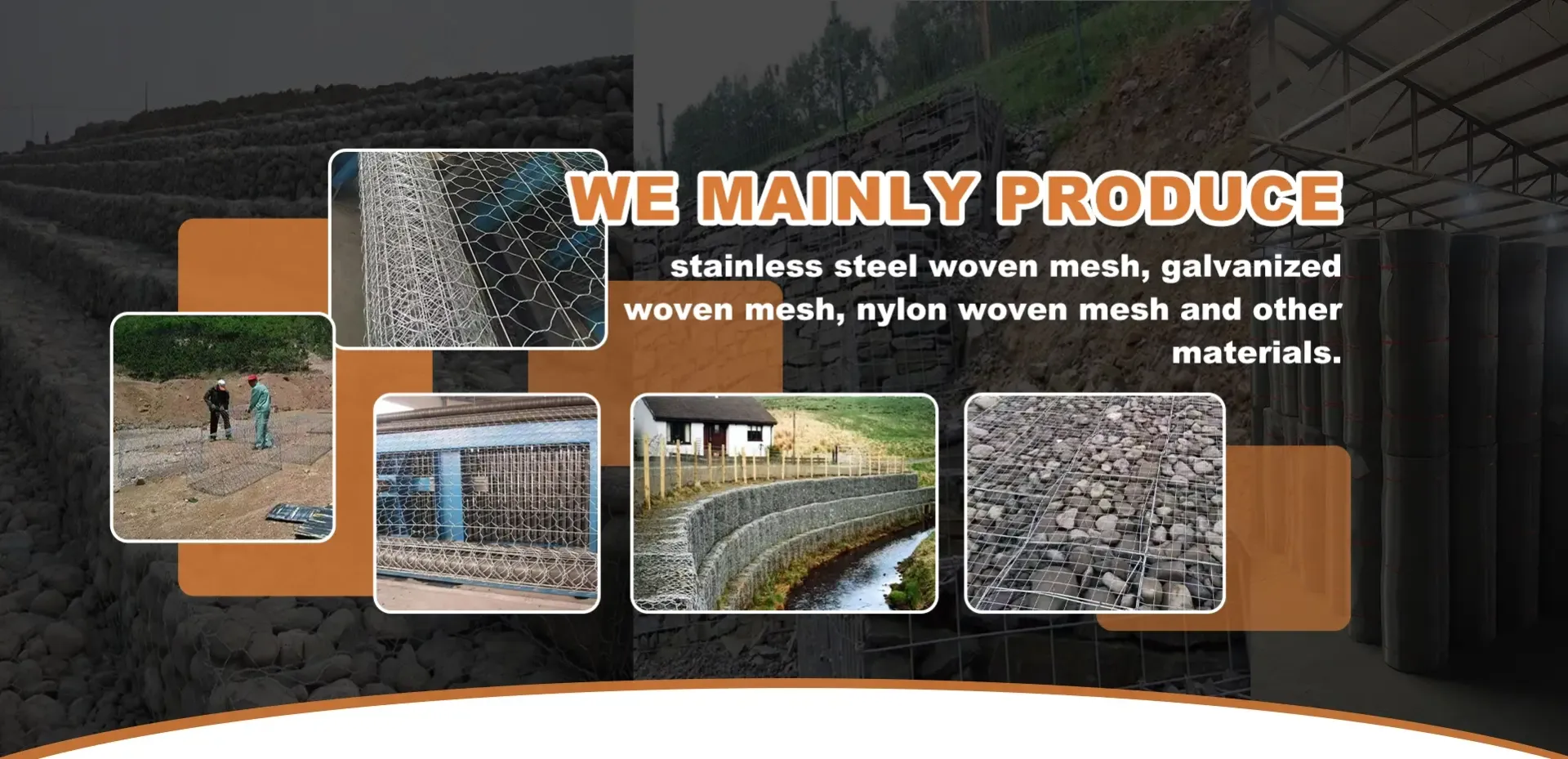

steel mesh manufacturers

Steel Mesh Manufacturers A Critical Component in Construction and Industry

In the ever-evolving world of construction and manufacturing, steel mesh has emerged as an essential material that offers strength, support, and versatility in a multitude of applications. Steel mesh manufacturers play a pivotal role in providing high-quality products that meet the growing demands of various industries, including construction, automotive, and agriculture. This article explores the significance of steel mesh, the processes involved in its production, and the key factors to consider when selecting a steel mesh manufacturer.

Understanding Steel Mesh

Steel mesh, often referred to as welded wire mesh or reinforcement mesh, is a grid-like assembly of steel wires that are welded at their intersections. This engineered product is designed to provide structural integrity to concrete and soil, enhancing load-bearing capacities and minimizing the risk of cracking. Its applications are vast, ranging from reinforcing concrete slabs and walls to fencing, drainage systems, and even architectural designs.

The primary benefit of steel mesh is its ability to distribute weight and forces evenly across a surface. In construction, it serves as a reinforcement material in floors, roofs, and bridges, ensuring that structures can withstand various loads and stresses over time.

The Manufacturing Process

The production of steel mesh involves several steps that require precision and expertise. The process begins with selecting high-quality steel wires, which are then drawn to specific diameters based on the desired specifications. Once prepared, these wires are arranged in a grid pattern.

Next, the wires are welded together at their intersections using automated welding machines. This process ensures that the mesh possesses the necessary strength and durability to meet industry standards. After welding, the steel mesh undergoes quality control checks to confirm that it meets the required specifications regarding dimensions, tensile strength, and surface finish.

Finally, the finished products may be treated with protective coatings or finishes to enhance their resistance to corrosion and environmental factors. Depending on the intended application, manufacturers may also offer customized solutions, such as varied wire diameters, spacing, and mesh sizes.

Key Considerations When Choosing a Steel Mesh Manufacturer

steel mesh manufacturers

Selecting a reliable steel mesh manufacturer is crucial for ensuring the quality and safety of construction projects. Here are several key factors to consider

1. Quality Standards Ensure that the manufacturer adheres to industry standards and certifications. Look for companies that have obtained ISO certification or comply with ASTM (American Society for Testing and Materials) standards, as these indicate a commitment to quality.

2. Experience and Expertise Evaluate the manufacturer’s experience in the industry. Companies that have been in operation for several years are likely to have a better understanding of market demands and customer needs. Additionally, consider manufacturers that specialize in the specific type of steel mesh required for your application.

3. Product Range A diversified product range often indicates a manufacturer’s ability to meet varying project requirements. Assess whether the manufacturer offers different types of steel mesh, custom sizes, and various finishes to suit specific applications.

4. Customer Support Strong customer service is essential in building a lasting partnership. Look for manufacturers that offer comprehensive support, from pre-sales consultations to post-sales assistance, ensuring that your needs are met throughout the purchasing process.

5. Pricing and Terms While pricing shouldn’t be the sole factor in your decision, it is important to evaluate whether the manufacturer’s pricing is competitive. Additionally, inquire about payment terms, delivery schedules, and bulk order discounts.

6. Environmental Responsibility Consider manufacturers that adopt sustainable practices in their production processes. An environmentally responsible company not only contributes to sustainability but also often meets the increasing demand for eco-friendly products in the construction industry.

Conclusion

Steel mesh manufacturers are integral to the construction and industrial sectors, providing vital products that enhance safety and structural integrity. By understanding the importance of steel mesh and considering the critical factors in choosing a manufacturer, businesses can ensure they are partnering with a quality supplier that meets their specific needs. As construction trends evolve, the role of these manufacturers will only continue to grow, making it essential to choose wisely for the success of any project.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025