-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

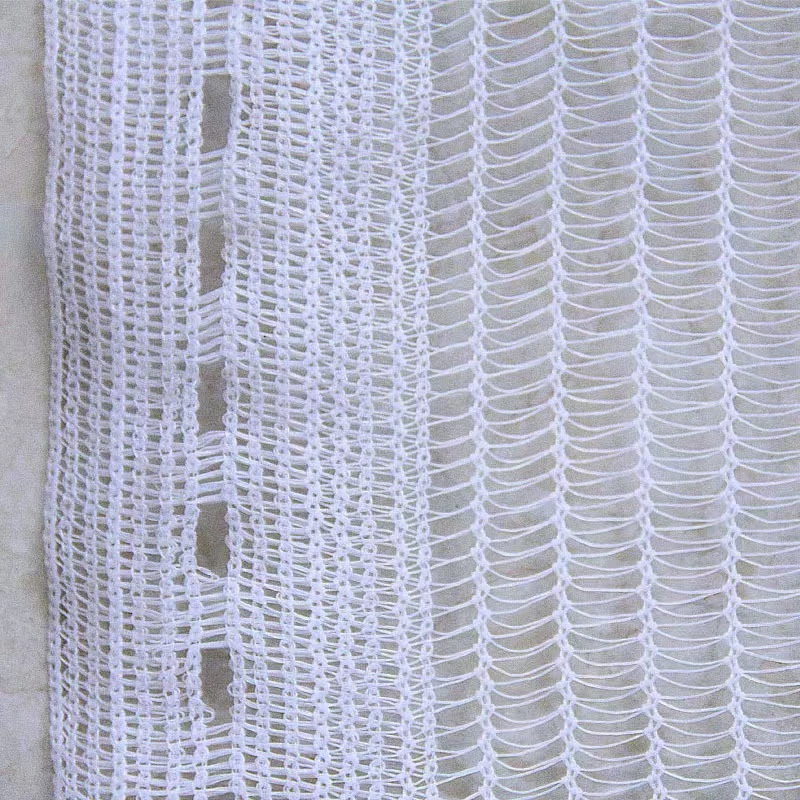

steel wire fabric

The Importance of Steel Wire Fabric in Modern Construction

In the realm of modern construction, the phrase steel wire fabric often surfaces, signifying a crucial element that contributes to the structural integrity and longevity of various constructions. Steel wire fabric, commonly referred to as welded wire mesh or simply wire mesh, is made from steel wires arranged in a grid pattern and welded at the intersections. This versatile product is extensively used in the construction of concrete structures, enhancing strength, durability, and overall performance.

Properties and Composition

Steel wire fabric is composed of high-quality steel that provides excellent tensile strength, making it resistant to various forms of stress and strain. The wires are offered in different diameters, which can be chosen based on the specific needs of the project. Additionally, the spacing between the wires can also be customized to accommodate various applications. This flexibility not only makes steel wire fabric a strong reinforcement material but also allows engineers and architects to design safer and more efficient structures.

Applications in Construction

One of the primary applications of steel wire fabric is in reinforced concrete construction. Concrete, while inherently strong in compression, lacks tensile strength. To mitigate this limitation, steel wire fabric is incorporated into concrete slabs, walls, and foundations. The mesh provides a reliable framework that holds the concrete in place and prevents cracking, which can occur due to temperature variations, settling, or dynamic loads.

Moreover, steel wire fabric is widely used in various other applications, including roadways, pavements, and precast concrete elements

. In road construction, for instance, the use of wire mesh can enhance the load-bearing capacity of the concrete and increase the lifespan of the surface, reducing maintenance costs over time. In precast concrete applications, the mesh ensures uniformity and strength, enabling manufacturers to produce high-quality components efficiently.steel wire fabric

Benefits of Steel Wire Fabric

One of the most significant benefits of steel wire fabric is its cost-effectiveness. By providing superior structural reinforcement, it allows for the reduction of concrete volume, leading to lower material costs. Additionally, the use of welded wire mesh saves time during the construction process, as it is easier to handle and install compared to traditional rebar. The prefabrication capabilities of steel wire fabric also result in less waste on construction sites, contributing to more sustainable building practices.

Another advantage of using steel wire fabric is its high resistance to corrosion, particularly when galvanized or coated. This characteristic is especially vital in regions where moisture is prevalent, as it prolongs the lifespan of the reinforcement and minimizes the need for frequent repairs or replacements. Furthermore, the uniform distribution of steel throughout the concrete leads to better performance under various load conditions, making structures safer and more reliable.

Future Trends in Steel Wire Fabric Technology

As construction technology evolves, the manufacturing and application of steel wire fabric are becoming even more innovative. Advances in materials science have led to the development of high-strength steel alloys that enhance the performance of wire mesh. Furthermore, the integration of smart technologies, such as sensors embedded within the wire fabric, has the potential to monitor the health of structures in real-time. This proactive approach to maintenance can significantly reduce risks associated with structural failures.

In conclusion, steel wire fabric plays an essential role in modern construction, offering a blend of strength, versatility, and cost efficiency. Its applications span across various types of structures, contributing to enhanced performance and safety. As we continue to embrace new technologies and materials, steel wire fabric remains a critical element in the pursuit of building resilient and sustainable infrastructures for the future.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025