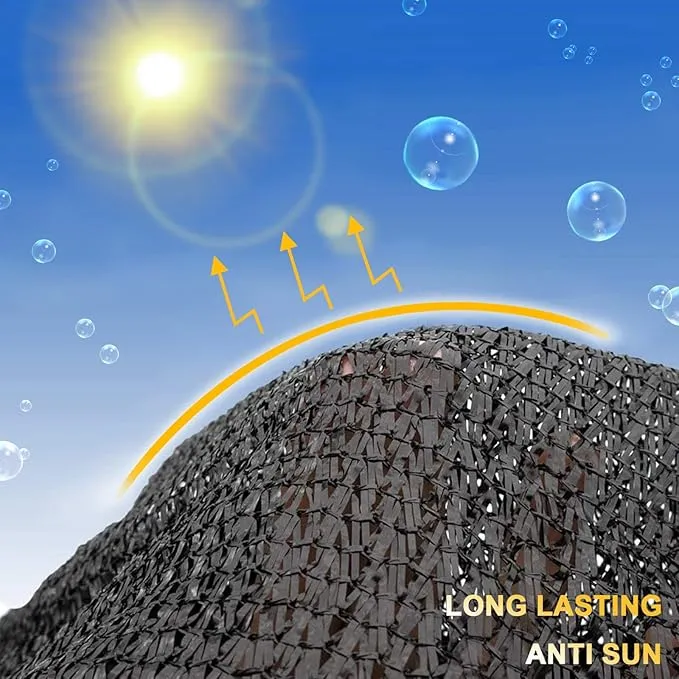

Sun Shade Mesh – UV-Stabilized, Durable, Breathable

A Field-Tested Look at Sun Shade Mesh for Greenhouses and Orchards

If you’ve worked a summer in a fruit block, you know the sun is both friend and foe. I’ve seen apples sunburn in an hour. That’s why modern growers lean hard on Sun Shade Mesh—not as a gimmick, but as insurance. Actually, it’s more than shade: it’s microclimate control, wind tempering, and even a bit of frost moderation in shoulder seasons.

What it’s made of (and why it matters)

Sun Shade Mesh typically uses high-density polyethylene (HDPE) with HALS UV stabilizers. The HDPE is lightweight yet robust; the stabilizers are the unsung heroes that keep it from chalking and cracking. Most quality rolls are Raschel-knitted—gives you stretch-ability with good tear resistance. Many customers say the “hand feel” tells them everything; in practice, GSM and tensile data do.

Typical specs (real-world use may vary)

| Material / Knit | HDPE with HALS UV, Raschel-knit |

| GSM | ≈ 80 / 120 / 160 / 220 g/m² options |

| Shade factor | ≈ 30%, 50%, 70%, 90% |

| Tensile strength | ≈ 1,200–1,800 N/5cm (warp), 900–1,400 N/5cm (weft) |

| Widths / Lengths | 1–8 m widths; 50–100 m rolls (custom on request) |

| Temperature range | ≈ -30°C to 75°C |

| Edges / Hardware | Reinforced selvedge; PE tape hem; eyelets or sewn loops |

From resin to roll: process and testing

- Materials: virgin HDPE + UV masterbatch; colorants (black/green/white) for spectral tuning.

- Methods: mono/flat yarn extrusion → Raschel knitting → edge reinforcement → QC.

- Testing: tensile per ISO 13934-1; tear per ASTM D2261; UV aging per ISO 4892-3 / ASTM G154; flammability screening per NFPA 701 (where required).

- Service life: 5–8 seasons in high UV zones; up to 10 in temperate climates with winter storage.

- Certs: ROHS/REACH declarations available from reputable mills.

Where it earns its keep

Greenhouses, hoop houses, orchard canopies (apples, cherries, citrus), nursery shade bays, livestock housing, poultry, even kennels and barn alleyways. Construction sites use Sun Shade Mesh for scaffold screens; sports facilities for fence privacy. In fact, you’ll see it on patios and carports too—people like the airflow.

Case notes from the field

- Orchard, NSW: 70% black Sun Shade Mesh cut sunburn losses ≈35% on Granny Smith; wind rub dropped notably.

- Seedling nursery, California: 50% white mesh improved uniformity; survival up ≈8% through a heatwave (grower logbooks).

- Dairy holding pen, Spain: 70% green mesh reduced radiant load; afternoon panting scores improved (informal observation, but telling).

Customization checklist

Pick your shade factor by crop stage, color for spectral response (white for diffuse light, black for heat cut), width to match spans, and edge style for your tension system. I guess the only trap: over-shading. Start at 30–50% for veg or young ornamentals; jump to 70–90% for livestock holding or carparks.

Who supplies what (quick comparison)

| Vendor | Country | GSM / Shade% | UV Warranty | MOQ | Certs |

|---|---|---|---|---|---|

| YJ Wire Mesh (this product) | China | 80–220 GSM / 30–90% | ≈ 5 years | Flexible | REACH, RoHS, test reports |

| Global Ag Net Co. | EU | 100–200 GSM / 40–80% | ≈ 4–6 years | Moderate | AS 4174, ROHS (selected lines) |

| Local Hardware Brand | Regional | ≈ 70–150 GSM / 30–70% | ≈ 2–3 years | Low | Basic compliance only |

Pros, trade-offs and a quick takeaway

- Advantages: airflow with protection, lower heat load, reduced sunburn and wind rub, easy to tension, long UV life.

- Trade-offs: very high shade can slow growth; cheap nets fray at edges; color choice affects canopy temperature.

- Pro tip: spec UV stabilization first, GSM second. And confirm test data—not just brochure talk.

Citations

- ISO 4892-3: Plastics — Exposure to laboratory light sources — Fluorescent UV lamps

- ASTM G154: Standard Practice for UV Exposure of Nonmetallic Materials

- ISO 13934-1: Textiles — Tensile properties of fabrics

- ASTM D2261: Tearing Strength of Fabrics by Tongue (Single Rip)

- AS 4174:2018 Knitted and woven shade fabrics

- NFPA 701: Flame Propagation of Textiles and Films

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025