-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

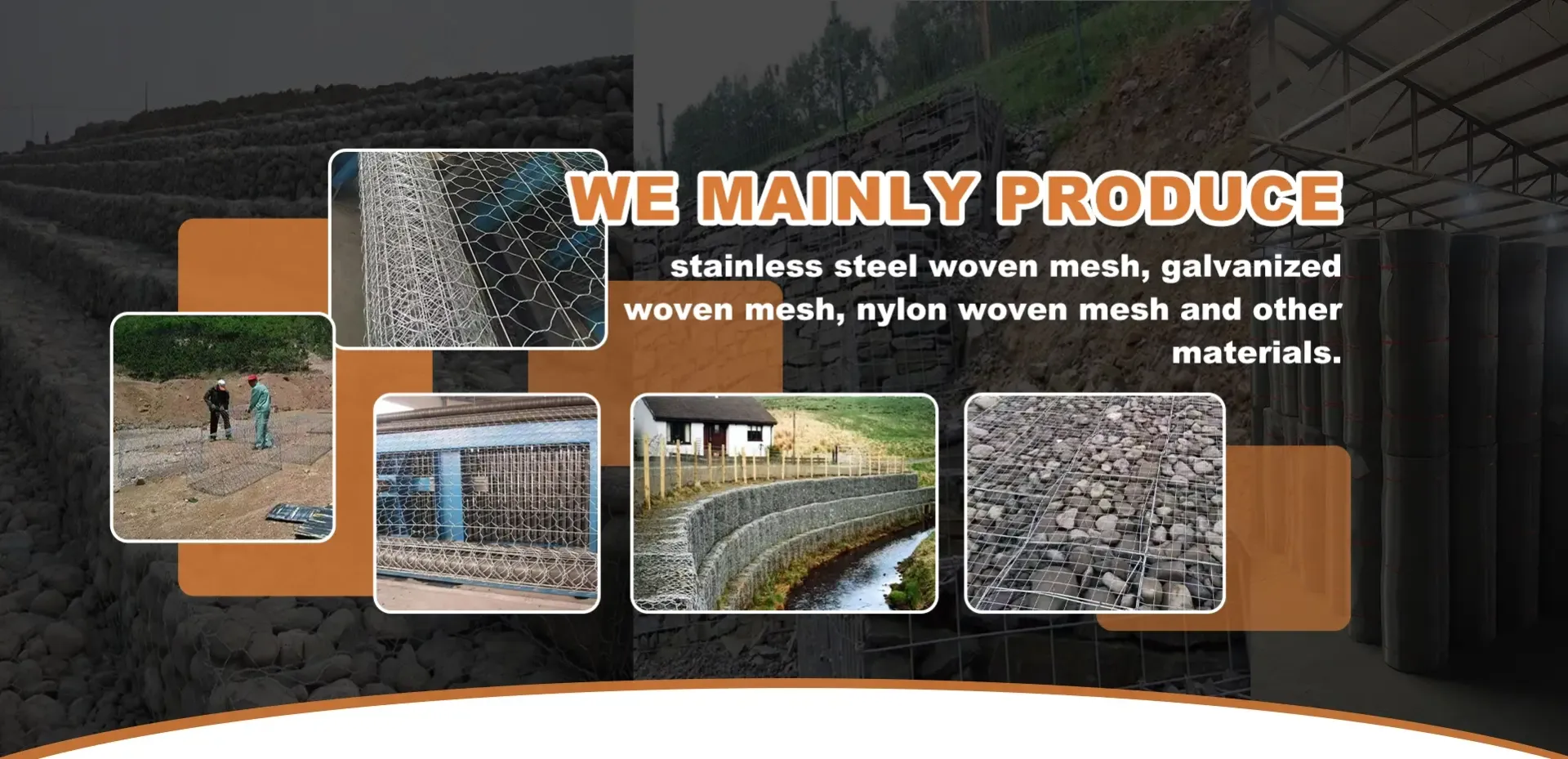

Top Stainless Steel Mesh Manufacturers for High-Quality Industrial Solutions and Custom Products

The Rise of Stainless Steel Mesh Manufacturers Meeting Modern Demands

In recent years, the demand for stainless steel mesh has surged across various industries due to its versatility, durability, and aesthetic appeal. Stainless steel mesh is utilized in a multitude of applications, including construction, filtration, automotive, and even art. As a result, the role of stainless steel mesh manufacturers has become increasingly significant in response to the growing market needs.

Stainless steel is a popular material choice because of its corrosion resistance, strength, and ability to withstand harsh environmental conditions. The mesh itself serves various purposes, from providing structural support to allowing for the flow of air, liquids, and light while preventing the passage of unwanted materials. In industries such as construction, stainless steel mesh is commonly used in reinforcing concrete, providing additional tensile strength, while in filtration, it is used to separate particles from liquids and gases, ensuring purity and safety.

The manufacturing process of stainless steel mesh has evolved significantly over the years. Modern manufacturers utilize advanced technologies, such as automation and precision machinery, to produce high-quality mesh that meets the specific requirements of their clients. These advancements not only improve efficiency but also ensure that the products adhere to strict industry standards. Moreover, manufacturers can offer various grades of stainless steel, each tailored to different environmental and operational conditions. This flexibility allows clients to choose the most suitable mesh for their specific applications, whether they require welded mesh, woven mesh, or perforated sheets.

Enhanced quality control processes have also become a hallmark of reputable stainless steel mesh manufacturers. Rigorous testing methods are employed to assess the strength, durability, and resistance of the mesh products. Manufacturers often seek certifications to demonstrate compliance with international standards, further instilling confidence in their clients regarding the reliability of their products. This emphasis on quality is particularly crucial in industries like food and beverage, pharmaceuticals, and chemical processing, where safety and hygiene are of utmost importance.

stainless steel mesh manufacturers

As the demand for stainless steel mesh continues to grow, manufacturers are also aware of the environmental impact of their operations. Sustainable practices in manufacturing processes, such as reducing waste, recycling scrap metal, and using eco-friendly packaging materials, have become common initiatives. Some manufacturers even invest in research and development to explore innovative ways to produce stainless steel mesh with a lower carbon footprint. This commitment to sustainability not only helps the environment but also appeals to increasingly eco-conscious consumers.

In addition to industrial applications, the aesthetic qualities of stainless steel mesh have captured the interest of architects and designers. Its sleek appearance and adaptability make it popular for decorative elements in modern architecture and interior design. As a result, manufacturers are increasingly collaborating with design professionals to create custom solutions that blend functionality with artistic expression.

To stay competitive in this rapidly evolving market, stainless steel mesh manufacturers must continuously adapt to changing customer needs and technological advancements. By investing in research and embracing new production techniques, they can enhance their product offerings and expand into new markets. Moreover, effective communication and strong relationships with clients are essential for understanding their requirements and providing customized solutions.

In conclusion, stainless steel mesh manufacturers play a crucial role in various industries, responding to the ever-increasing demand for their products. Through advanced manufacturing processes, stringent quality control, and a commitment to sustainability, they not only supply essential materials but also contribute to innovative and aesthetically pleasing designs. As the market evolves, these manufacturers will continue to be at the forefront, meeting the challenges of the future while providing outstanding products for a diverse range of applications.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025