-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

welded steel wire fabric

The Versatility and Applications of Welded Steel Wire Fabric

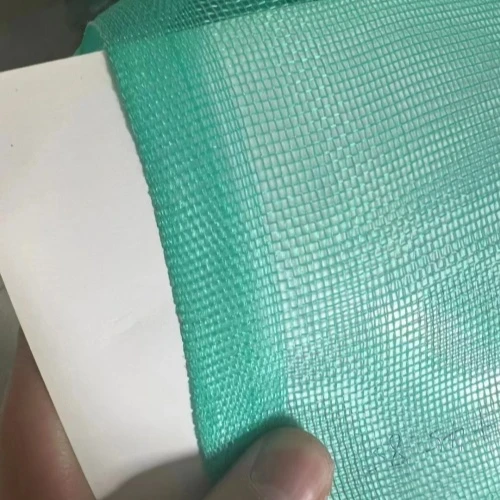

Welded steel wire fabric, commonly known as wire mesh, is an essential building material composed of a matrix of steel wires that are welded together to form a grid or mesh pattern. This construction material has gained widespread recognition and is indispensable in a variety of construction, industrial, and architectural applications. Understanding the advantages and uses of welded steel wire fabric is crucial for anyone involved in the construction industry or in search of robust materials.

Composition and Production

Welded steel wire fabric is created through the process of electric resistance welding, where intersecting wires are fused together at their junctions. Typically, the mesh comes in various sizes, with wire diameters ranging from 3 mm to 12 mm, and the spacing between the wires can vary based on the specific requirements of the project. The manufacturing process ensures that the mesh retains its shape and structural integrity, allowing it to withstand significant loads.

One of the primary advantages of using welded steel wire fabric is its strength and durability. The welding process enhances the load-bearing capacity of the fabric, making it ideal for use in concrete reinforcement. The mesh is often integrated into slabs, pavements, and walls to improve structural stability and mitigate cracking due to shrinkage or external forces.

Applications in Construction

The applications of welded steel wire fabric are extensive, with its most prominent use being in reinforced concrete structures. In this context, the mesh acts as a spine, providing tensile strength that complements the compressive strength of concrete. This combination allows for the construction of larger and more resilient structures such as bridges, highways, and buildings.

welded steel wire fabric

Besides concrete reinforcement, welded steel wire fabric is used for various other applications. It is commonly used in flooring systems, where it can be embedded within the surface to enhance its durability. The fabric is also utilized in precast concrete elements, contributing to the structural integrity of panels, beams, and columns.

In the realm of fencing, welded steel wire fabric is an excellent choice due to its durability and resistance to corrosive elements. It is often employed in residential, commercial, and industrial fencing applications, providing reliable security without compromising visibility.

Environmental Impact and Sustainability

As sustainability becomes an increasing concern in construction, welded steel wire fabric offers an eco-friendly alternative. Steel is a highly recyclable material, making it a sustainable option for construction projects. The longevity and strength of the fabric also mean that it can withstand the test of time, reducing the need for repairs or replacements and ultimately minimizing waste.

Furthermore, the production of welded steel wire fabric involves less energy compared to other types of steel reinforcement, leading to a lower overall carbon footprint. Therefore, using this material aligns with the broader goals of sustainable architecture and construction practices.

Conclusion

Welded steel wire fabric stands out as a versatile and robust material that has transformed modern construction. Its strength, durability, and adaptability to various applications make it an indispensable component in building projects across the globe. As the industry continues to evolve, the importance of sustainable materials like welded steel wire fabric will only grow. Understanding its properties and applications not only empowers construction professionals but also encourages a shift towards more responsible building practices. Whether it's reinforcing concrete, building fences, or developing sustainable architectural solutions, welded steel wire fabric proves to be a reliable choice in the toolkit of modern construction.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025