-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 19, 2025 04:32

Back to list

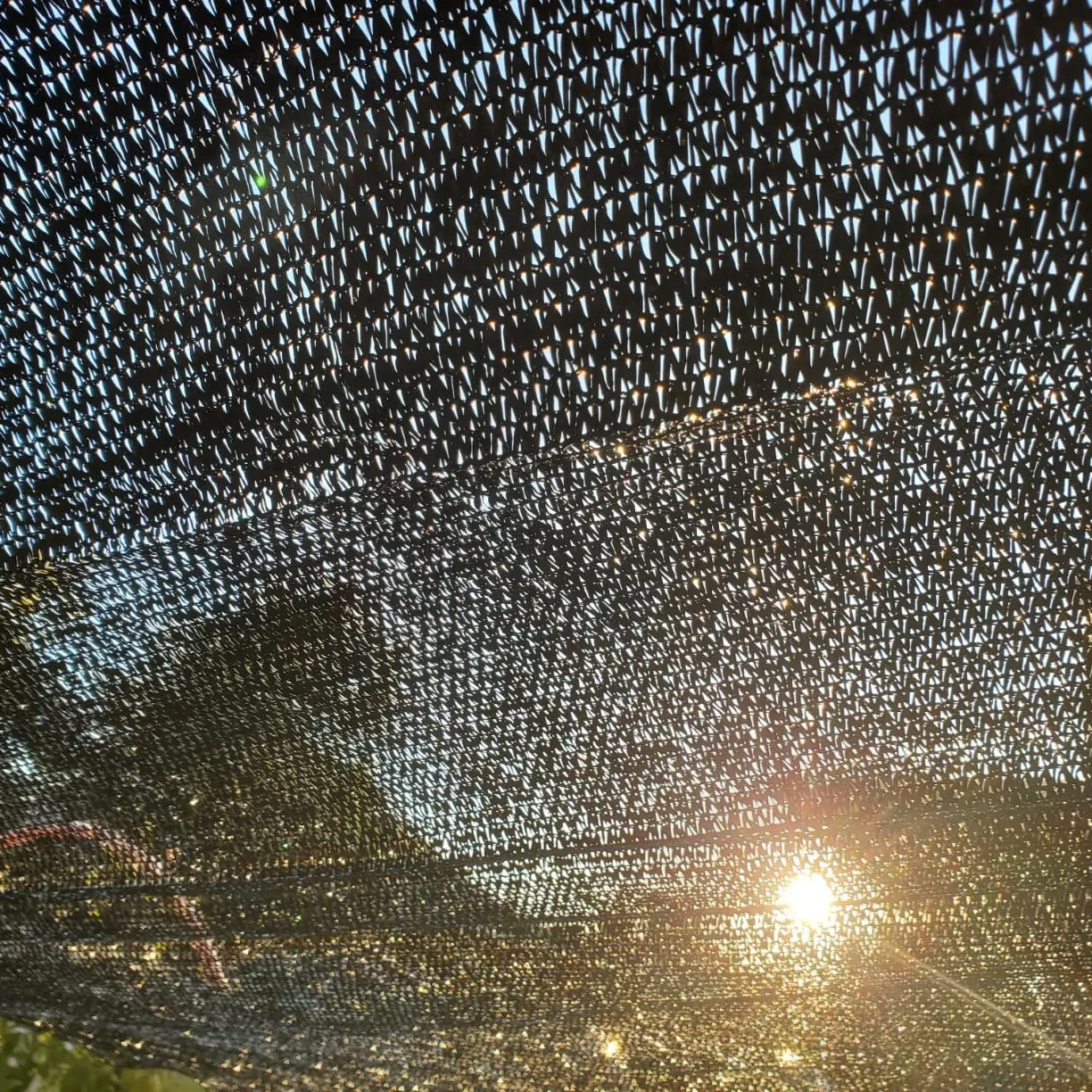

100% HDPE Agricultural Bird Proof Netting Knotted Heavy-Duty Bird Netting

Woven steel mesh has emerged as a compelling solution in various industries, combining durability with versatility to meet an array of application needs. This unique material is rigorously engineered, involving a precise interlacing of wires that results in a robust product capable of offering both strength and aesthetic appeal. Such characteristics make it ideal for sectors ranging from construction to art installations, each benefiting significantly from its distinguished properties.

From an expertise standpoint, working with woven steel mesh requires a comprehensive understanding of its specifications and properties. Selection of the appropriate mesh type involves consideration of factors like wire diameter, aperture size, and tensile strength, tailored to the intended application. Professionals in this field leverage their knowledge to customize mesh configurations, ensuring optimal performance and adherence to industry standards. Authoritative voices in the industry, such as engineers and material scientists, advocate for its use due to its unparalleled combination of strength, flexibility, and environmental resistance. Research and development continue to advance, with enhancements focused on improving manufacturing processes and the mesh's adaptability to new, innovative uses. Trends indicate an increasing inclination towards sustainability, with efforts directed at recycling and reusing steel mesh, thus minimizing environmental impact without sacrificing quality. Trust in woven steel mesh is built on decades of proven performance across numerous industries. Its adoption is supported by rigorous testing and quality assurance measures that adhere to international standards. Manufacturers provide certification and documentation that attest to the material's compliance with safety and environmental regulations, reinforcing customer confidence. In conclusion, woven steel mesh symbolizes a fusion of innovation and utility, tailor-made to address the ever-evolving challenges of modern industries. Its diverse range of applications and reliability cements its place as a foundational component underpinning the safety, efficiency, and aesthetic appeal of contemporary projects. The continued evolution of this material promises to broaden its impact, solidifying its status as an indispensable resource in the professional world.

From an expertise standpoint, working with woven steel mesh requires a comprehensive understanding of its specifications and properties. Selection of the appropriate mesh type involves consideration of factors like wire diameter, aperture size, and tensile strength, tailored to the intended application. Professionals in this field leverage their knowledge to customize mesh configurations, ensuring optimal performance and adherence to industry standards. Authoritative voices in the industry, such as engineers and material scientists, advocate for its use due to its unparalleled combination of strength, flexibility, and environmental resistance. Research and development continue to advance, with enhancements focused on improving manufacturing processes and the mesh's adaptability to new, innovative uses. Trends indicate an increasing inclination towards sustainability, with efforts directed at recycling and reusing steel mesh, thus minimizing environmental impact without sacrificing quality. Trust in woven steel mesh is built on decades of proven performance across numerous industries. Its adoption is supported by rigorous testing and quality assurance measures that adhere to international standards. Manufacturers provide certification and documentation that attest to the material's compliance with safety and environmental regulations, reinforcing customer confidence. In conclusion, woven steel mesh symbolizes a fusion of innovation and utility, tailor-made to address the ever-evolving challenges of modern industries. Its diverse range of applications and reliability cements its place as a foundational component underpinning the safety, efficiency, and aesthetic appeal of contemporary projects. The continued evolution of this material promises to broaden its impact, solidifying its status as an indispensable resource in the professional world.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025