-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 26, 2025 08:31

Back to list

Nylon Filter Mesh

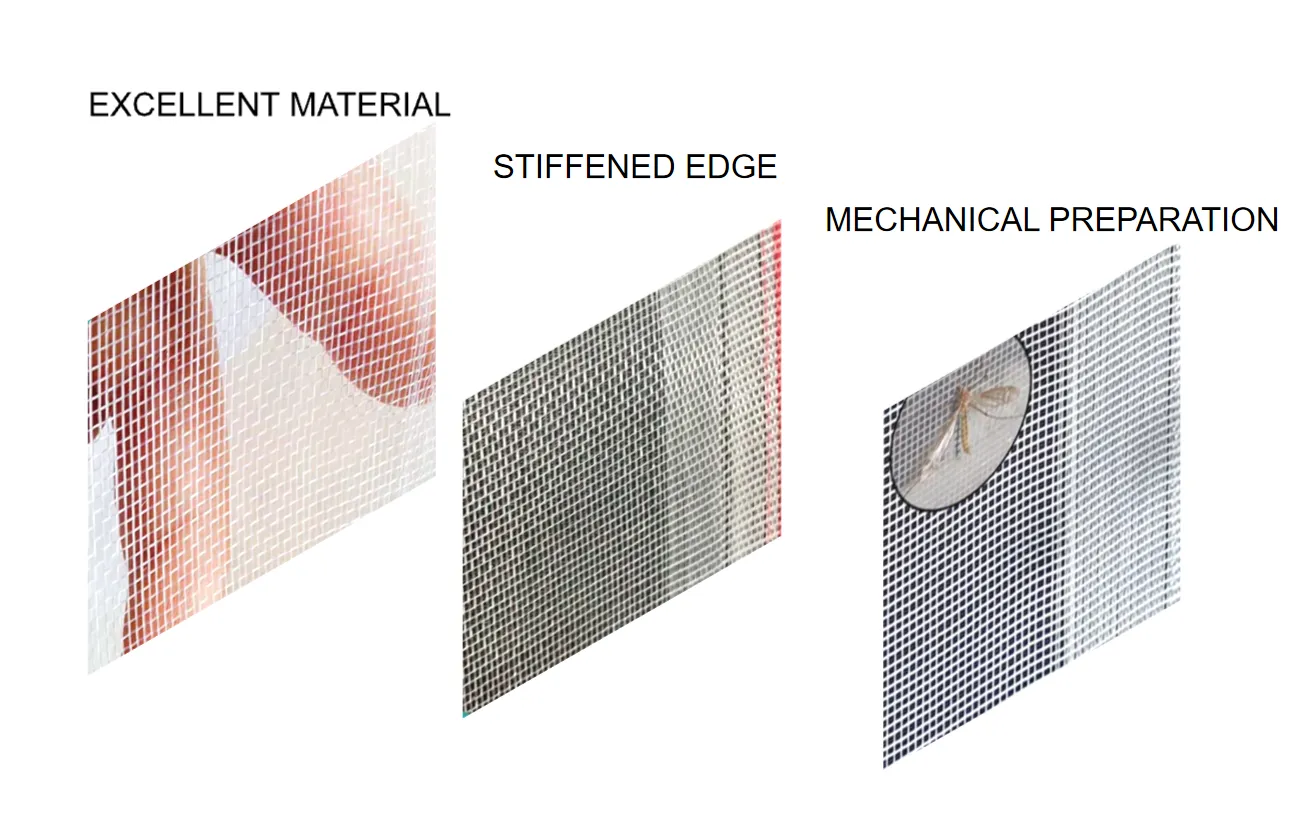

Steel fabric reinforcement mesh, a crucial element in modern construction, is reshaping the way we build structures. This high-strength, precision-engineered material is increasingly becoming the backbone for projects ranging from high-rise buildings to bridges and highways. What sets this product apart is its exceptional blend of flexibility, durability, and cost-effectiveness, making it a preferred choice among construction professionals.

Trustworthiness in construction materials is imperative. Steel fabric reinforcement mesh has been subjected to extensive research and testing in various environmental conditions, affirming its longevity and performance consistency. Clients and builders frequently share success stories where this material has played a critical role in extending the lifespan of infrastructures and reducing maintenance costs. One of the key advantages of using steel fabric reinforcement mesh is its environmental footprint. Steel, being 100% recyclable, contributes positively to sustainable building practices. Its robustness means that over the lifecycle of a project, less material may be required for repairs or replacements, thereby reducing waste and resource consumption. This aspect particularly appeals to ecologically-conscious developers aiming to achieve green certifications for their projects. In summary, the rise in popularity of steel fabric reinforcement mesh among construction experts is driven by its efficiency in use, superior manufacturing quality, adherence to industry standards, and environmentally sustainable attributes. As the construction industry continues to evolve toward smarter, faster, and more eco-friendly practices, steel fabric reinforcement mesh stands out as a dependable choice that meets the rigorous demands of modern infrastructure projects.

Trustworthiness in construction materials is imperative. Steel fabric reinforcement mesh has been subjected to extensive research and testing in various environmental conditions, affirming its longevity and performance consistency. Clients and builders frequently share success stories where this material has played a critical role in extending the lifespan of infrastructures and reducing maintenance costs. One of the key advantages of using steel fabric reinforcement mesh is its environmental footprint. Steel, being 100% recyclable, contributes positively to sustainable building practices. Its robustness means that over the lifecycle of a project, less material may be required for repairs or replacements, thereby reducing waste and resource consumption. This aspect particularly appeals to ecologically-conscious developers aiming to achieve green certifications for their projects. In summary, the rise in popularity of steel fabric reinforcement mesh among construction experts is driven by its efficiency in use, superior manufacturing quality, adherence to industry standards, and environmentally sustainable attributes. As the construction industry continues to evolve toward smarter, faster, and more eco-friendly practices, steel fabric reinforcement mesh stands out as a dependable choice that meets the rigorous demands of modern infrastructure projects.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025