-

افریقی

افریقی -

البانوی

البانوی -

امہاری

امہاری -

عربی

عربی -

آرمینیائی

آرمینیائی -

آذربائیجانی

آذربائیجانی -

باسکی

باسکی -

بیلاروسی

بیلاروسی -

بنگالی

بنگالی -

بوسنیائی

بوسنیائی -

بلغاریائی

بلغاریائی -

کاتالان

کاتالان -

سیبوانو

سیبوانو -

چین

چین -

کورسیکن

کورسیکن -

کروشین

کروشین -

چیک

چیک -

ڈینش

ڈینش -

ڈچ

ڈچ -

انگریزی

انگریزی -

ایسپرانٹو

ایسپرانٹو -

اسٹونین

اسٹونین -

فنش

فنش -

فرانسیسی

فرانسیسی -

فریسیئن

فریسیئن -

گالیشین

گالیشین -

جارجیائی

جارجیائی -

جرمن

جرمن -

یونانی

یونانی -

گجراتی

گجراتی -

ہیٹی کریول

ہیٹی کریول -

ہاؤسا

ہاؤسا -

ہوائی

ہوائی -

عبرانی

عبرانی -

nope کیا

nope کیا -

میاؤ

میاؤ -

ہنگری

ہنگری -

آئس لینڈی

آئس لینڈی -

igbo

igbo -

انڈونیشین

انڈونیشین -

آئرش

آئرش -

اطالوی

اطالوی -

جاپانی

جاپانی -

جاویانی

جاویانی -

کنڑ

کنڑ -

قازق

قازق -

خمیر

خمیر -

روانڈا

روانڈا -

کورین

کورین -

کرد

کرد -

کرغیز

کرغیز -

ٹی بی

ٹی بی -

لاطینی

لاطینی -

لیٹوین

لیٹوین -

لتھوانیائی

لتھوانیائی -

لکسمبرگش

لکسمبرگش -

مقدونیائی

مقدونیائی -

مالگاشی

مالگاشی -

مالائی

مالائی -

ملیالم

ملیالم -

مالٹیز

مالٹیز -

ماوری

ماوری -

مراٹھی

مراٹھی -

منگول

منگول -

میانمار

میانمار -

نیپالی

نیپالی -

ناروے

ناروے -

ناروے

ناروے -

آکسیٹن

آکسیٹن -

پشتو

پشتو -

فارسی

فارسی -

پولش

پولش -

پرتگالی

پرتگالی -

پنجابی

پنجابی -

رومانیہ

رومانیہ -

روسی

روسی -

سامون

سامون -

سکاٹش گیلک

سکاٹش گیلک -

سربیائی

سربیائی -

انگریزی

انگریزی -

شونا

شونا -

سندھی

سندھی -

سنہالا

سنہالا -

سلوواک

سلوواک -

سلووینیائی

سلووینیائی -

صومالی

صومالی -

ہسپانوی

ہسپانوی -

سنڈانی

سنڈانی -

سواحلی

سواحلی -

سویڈش

سویڈش -

ٹیگالوگ

ٹیگالوگ -

تاجک

تاجک -

تامل

تامل -

تاتار

تاتار -

تیلگو

تیلگو -

تھائی

تھائی -

ترکی

ترکی -

ترکمان

ترکمان -

یوکرینی

یوکرینی -

اردو

اردو -

ایغور

ایغور -

ازبک

ازبک -

ویتنامی

ویتنامی -

ویلش

ویلش -

مدد

مدد -

یدش

یدش -

یوروبا

یوروبا -

زولو

زولو

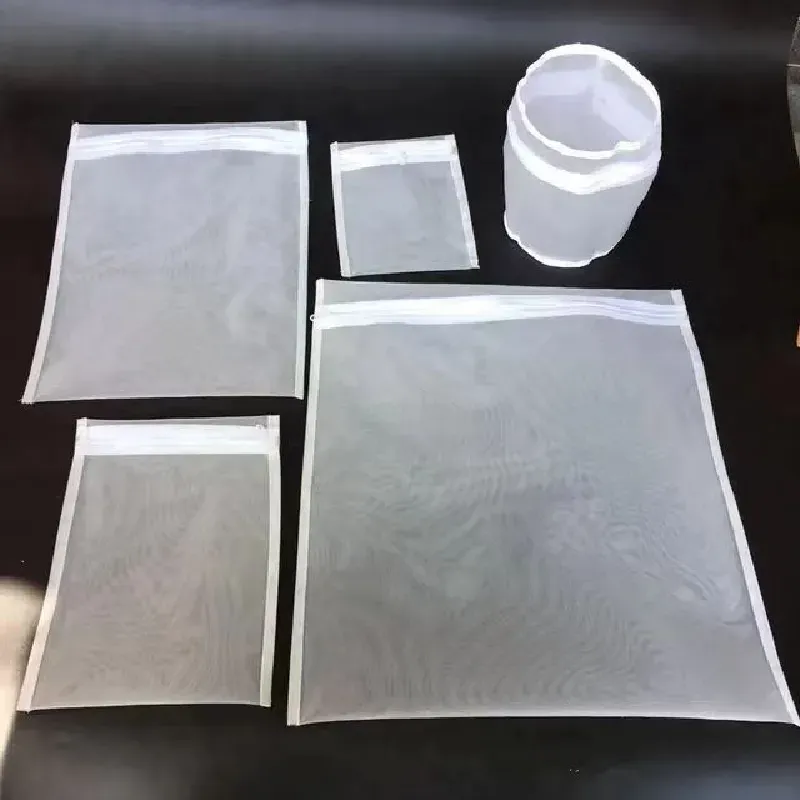

Application and Development of Nylon Screen in Fuel Processing and Treatment

Nylon screen has occupied an important position in the field of fuel processing because of its excellent physical properties and chemical stability. Whether in coal screening, bio-fuel separation or petroleum refining, nylon screen has shown high applicability and reliability.

Application of Nylon Screen in Fuel Industry

- Coal screening and preparation: In the process of coal processing, it is necessary to screen raw coal to remove sediment, stones and other impurities, and at the same time classify coal according to particle size to meet the needs of different combustion equipment. With its high strength and wear resistance, nylon screenhas been widely used in vibrating screen, roller screen and other equipment.

- Filtration and separation in petrochemical industry: In the process of petroleum refining and chemical industry, نایلان میشcan be used to separate suspended solid particles in crude oil and ensure the purity of oil products in the process of refined oil filtration. Especially in some crude oil treatment with more sand, nylon screenshows excellent anti-blocking performance.

- Liquid-solid separation in biofuel production: In the production of biofuels (such as ethanol, biogas and biodiesel), it is often necessary to separate solid substances from fermentation broth or waste. Nylon screenis widely used in centrifuges, filters and other equipment for its fine mesh and chemical corrosion resistance, ensuring efficient and stable separation process.

- Liquefaction and purification of natural gas: In the process of natural gas liquefaction and transportation, نایلان جالis used to filter solid particles and impurities in the transportation pipeline, prevent pipeline blockage and equipment wear, and ensure the purity and transmission efficiency of natural gas.

- Filtration of fuel additives: During the production and use of fuel additives (such as detergents and antioxidants), it is necessary to filter the solution to remove insoluble particles or control the particle size of additives. The chemical stability and high precision of nylon screenensure the efficient operation of this link.

Use and Maintenance of Nylon Screen

In order to ensure the best performance of nylon screen in fuel processing, the following are some suggestions for use and maintenance:

-

Regular cleaning: particles and impurities in fuel processing are easy to block the screen, so it should be cleaned regularly to keep the mesh open and ensure the screening efficiency.

-

Control tension: nylon screenshould be properly tensioned during installation. Too loose will affect the screening effect, while too tight may lead to mesh deformation or screen damage.

-

Prevention of mechanical damage: During use, the screen should be prevented from being scratched by sharp objects, and the equipment should run smoothly to prevent the screen from being damaged due to strong impact.

-

Regular inspection and replacement: Although the nylon mesh nettinghas a long service life, it may still be aging in a long-term high-load environment, so it needs to be inspected regularly and replaced as appropriate.

-

Avoid exceeding the temperature tolerance range: Although nylon screenhas certain high temperature resistance, it may lead to material performance degradation in an environment above its tolerance range, which should be avoided as far as possible.

Future Development Trend of Nylon Screen

-

Modification of new materials: By modifying نایلان فلٹر میش, such as adding nanoparticles or coating technology, its wear resistance, anti-blocking performance and high temperature resistance can be further improved.

-

Intelligent screen equipment: Combined with sensor technology, intelligent screen equipment that can monitor the mesh state, particle distribution and separation efficiency in real time is developed to improve the automation level of processing.

-

Optimization of environmental protection performance: develop more environmentally friendly nylon mesh materialsor biodegradable screens to further reduce the environmental impact of screen manufacturing and use.

-

High-precision microfiltration technology: meet the requirements of the fuel industry for the classification and separation of ultrafine particles, develop a nylon screenwith higher precision, and further improve the fuel quality.

-

The Sunshade Net Can Block Ultraviolet RaysخبریںAug.11,2025

-

Main Application and Technology of Nylon ScreenخبریںAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceخبریںAug.11,2025

-

Explore the Sunshade NetخبریںAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureخبریںAug.11,2025