Poner en pantalla: Screening refers to the process of classifying substances by separating different sizes or shapes using various technologies such as vibrating screens, trommel screens or rotary screens. It is mostly used in metallurgy, petrochemical, automobile, plastics and other industries to screen solid particles and powders.

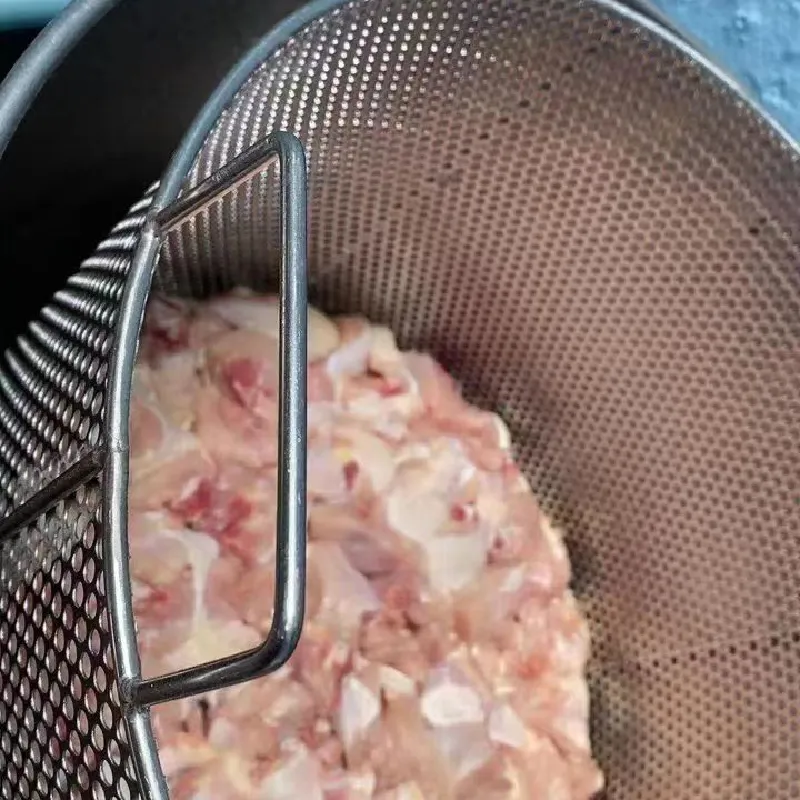

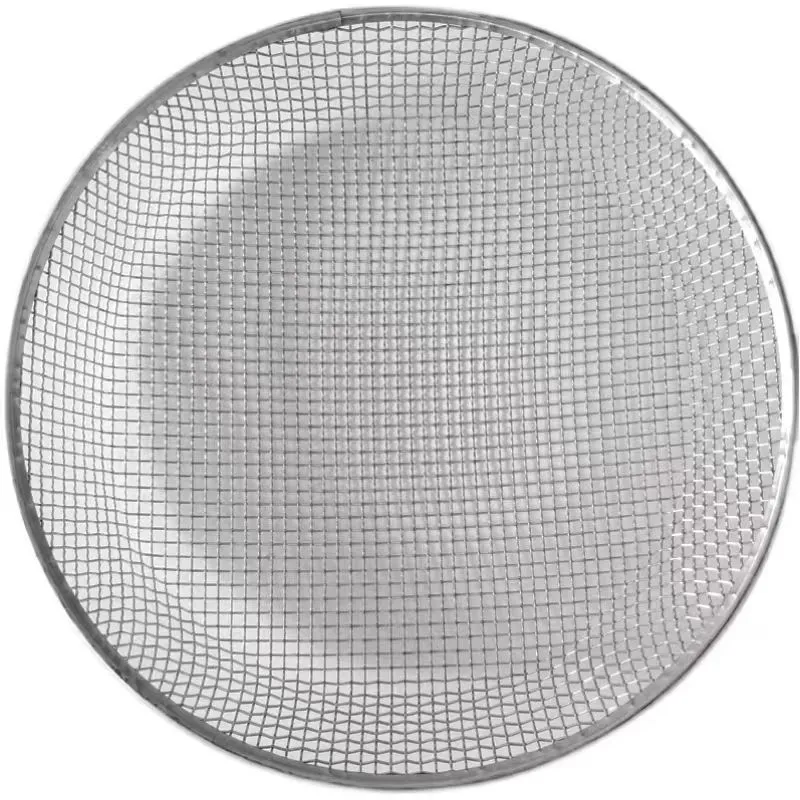

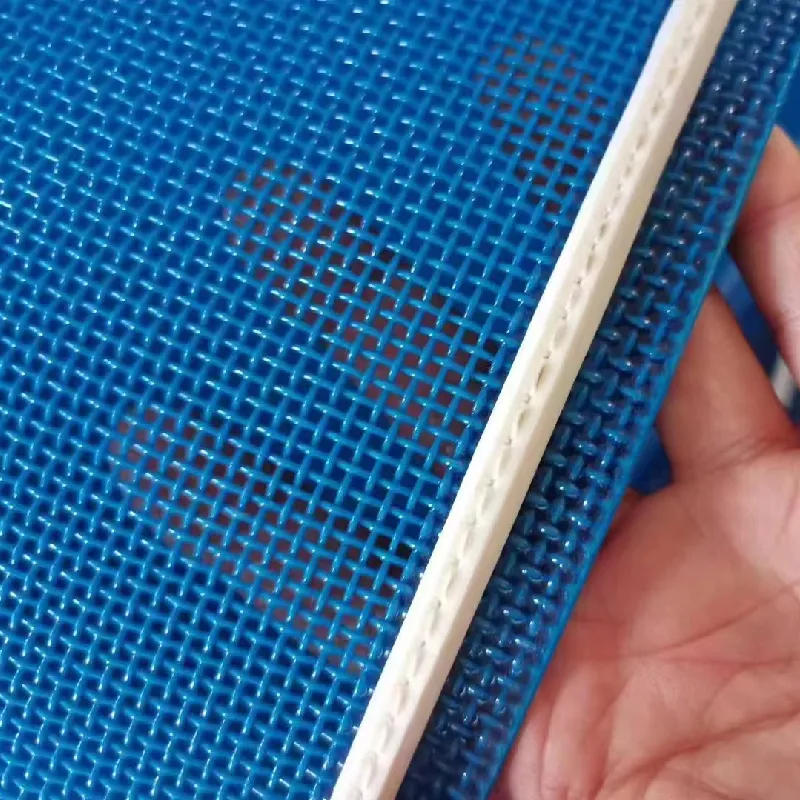

Filtración: Wire mesh filtration is a common filtration technology, mostly used for filtration of liquids, gases and other media. It uses the pores of the wire mesh to remove impurities in the medium to achieve the purpose of filtration. It is mostly used in wastewater treatment, food processing, pharmaceuticals, paints and coatings, etc.

Impresión: It is a technology that uses patterns or words on the screen to print ink or paint onto the printing material through pressure to form the desired pattern or words. It is characterized by good printing effect, low cost and simple operation. It is mostly used in textiles, electronic products, glass products, pharmaceutical packaging, etc.

Blindaje: El blindaje de malla de alambre es una tecnología que utiliza la conductividad metálica de la malla de alambre para proteger las ondas electromagnéticas dentro de la malla de alambre para lograr propósitos de blindaje. Se utiliza principalmente para el funcionamiento normal de equipos electrónicos, equipos de comunicación, equipos médicos y equipos de aviación.

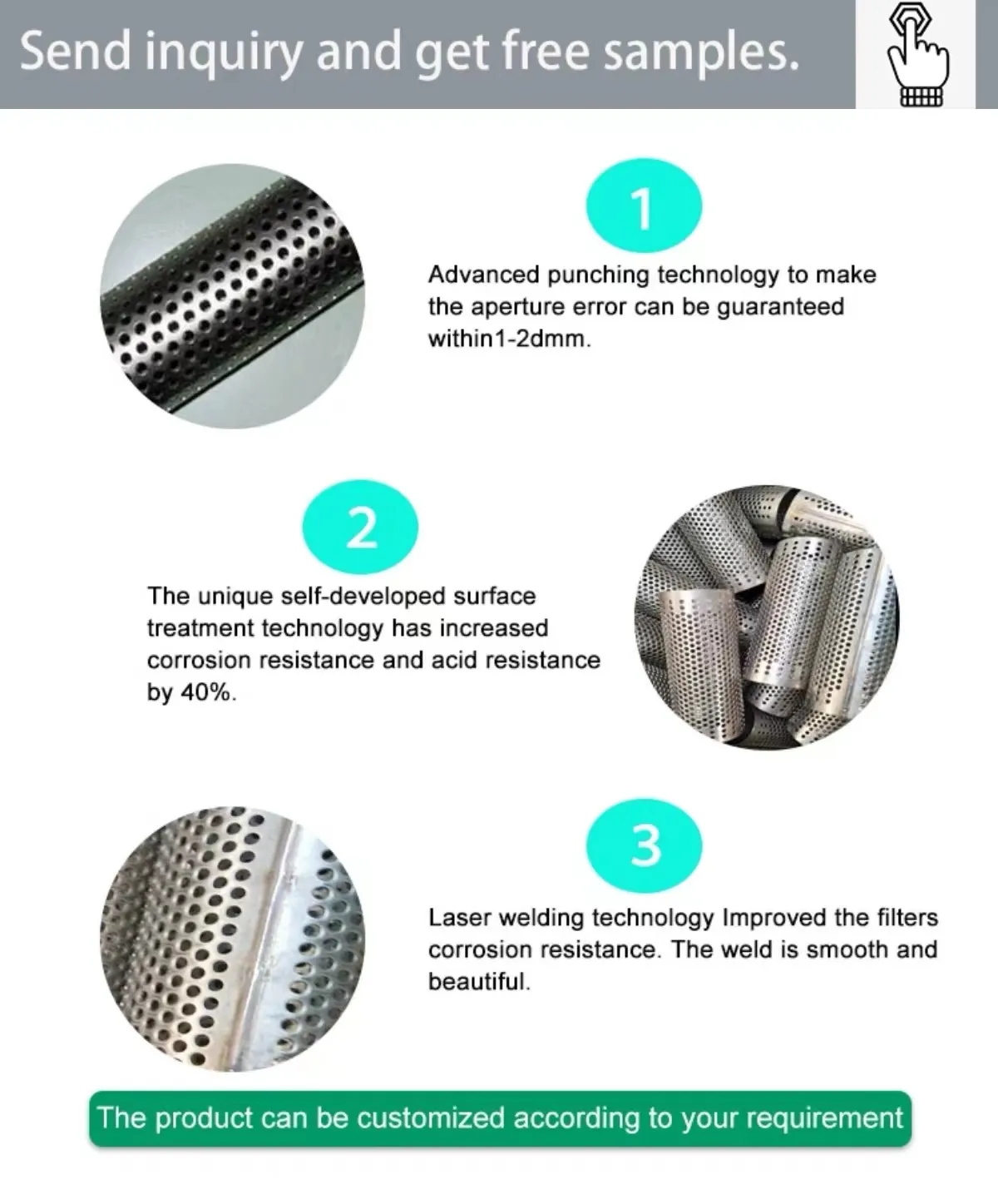

Choose stainless steel wire mesh, stainless steel mat mesh, copper wire mesh, stainless steel punched mesh, expanded steel mesh, and stainless steel filter mesh barrel.

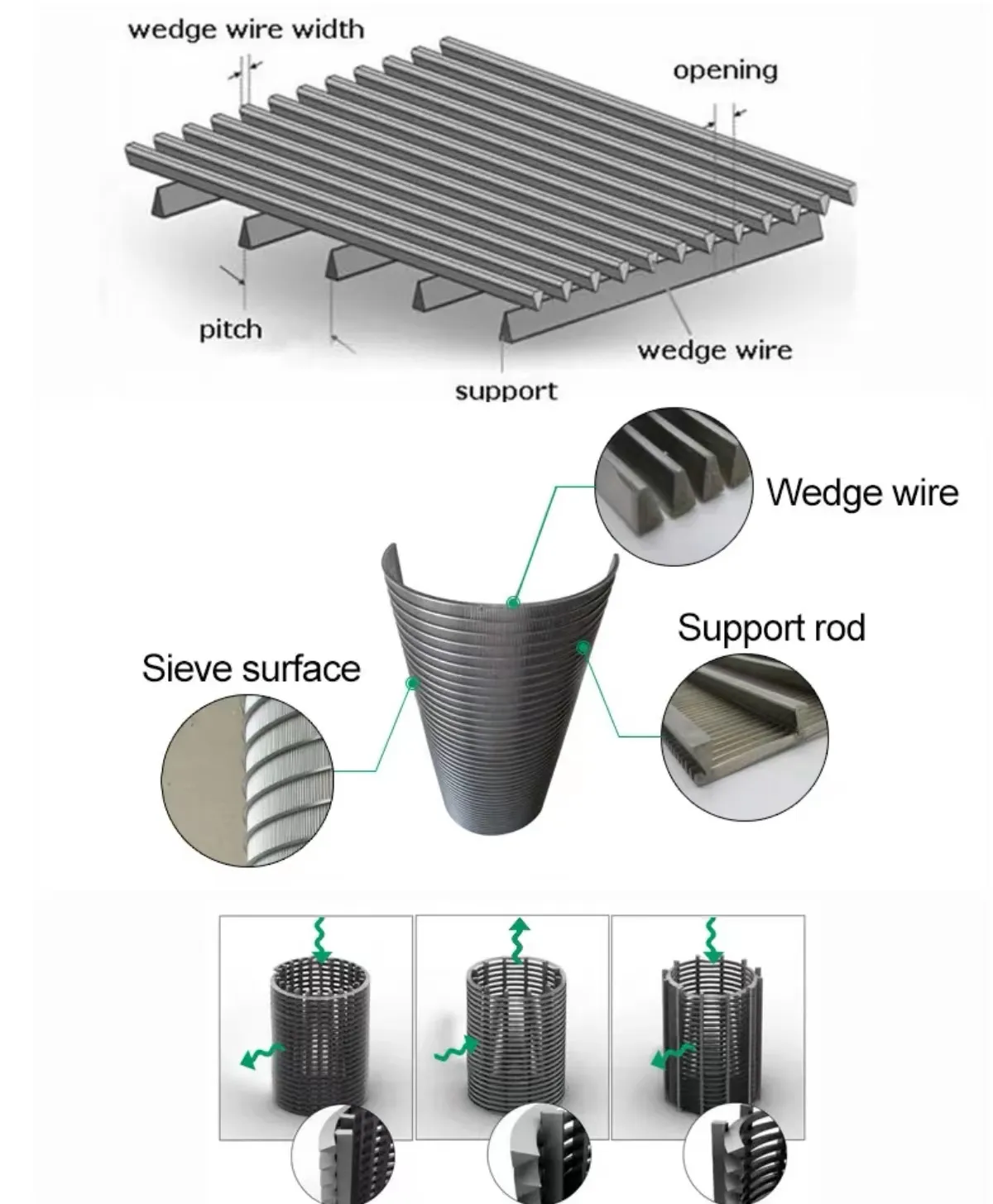

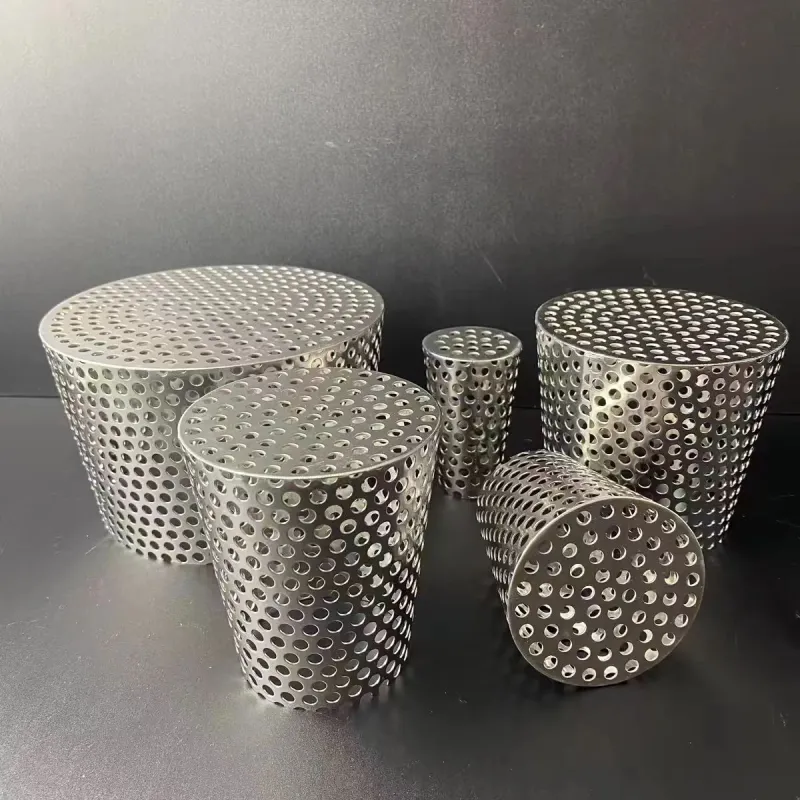

What types of filter cartridges are there?

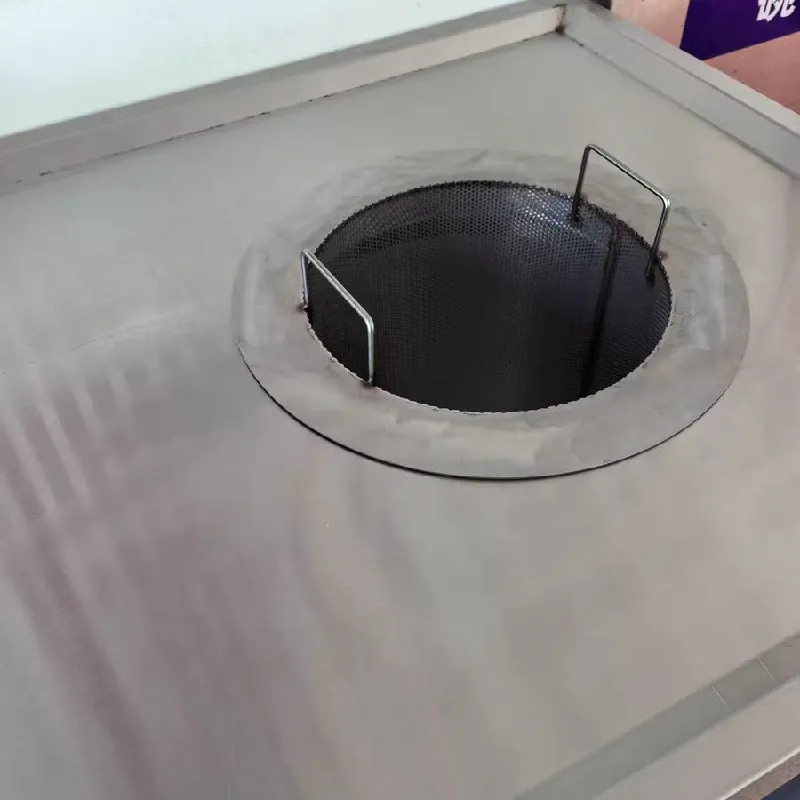

Stainless steel filter cylinder, punched mesh filter cylinder, stainless steel mat mesh cylinder, conical filter cylinder, cylindrical filter cylinder, edged filter cylinder, filter cylinder with handle, double or multi-layer filter cylinder, outer Braided mesh filter cylinder inside punched mesh, etched mesh filter cylinder, special-shaped filter cylinder, etc.

2. ¿Cuáles son las dimensiones del cartucho filtrante?

Because the needs of various industries are different, there are no unified specifications and sizes. All filter cartridges are customized according to customer requirements.

3. ¿Qué tipo de proceso de soldadura se utiliza para el cartucho filtrante?

Utilice soldadura por puntos o soldadura completa, soldadura directa o soldadura en espiral, o soldadura por arco de argón.

Hay algunas muestras de cartuchos de filtro, pero debido a los diferentes números, estructuras y tamaños de malla, las muestras existentes a menudo no pueden cumplir con los requisitos del cliente. Las muestras existentes sólo se utilizan para demostrar que podemos producir este o aquel tipo de cartucho de filtro (bienvenido a consultar sobre las imágenes)