Screening: Screening refers to the process of classifying substances by separating different sizes or shapes using various technologies such as vibrating screens, trommel screens or rotary screens. It is mostly used in metallurgy, petrochemical, automobile, plastics and other industries to screen solid particles and powders.

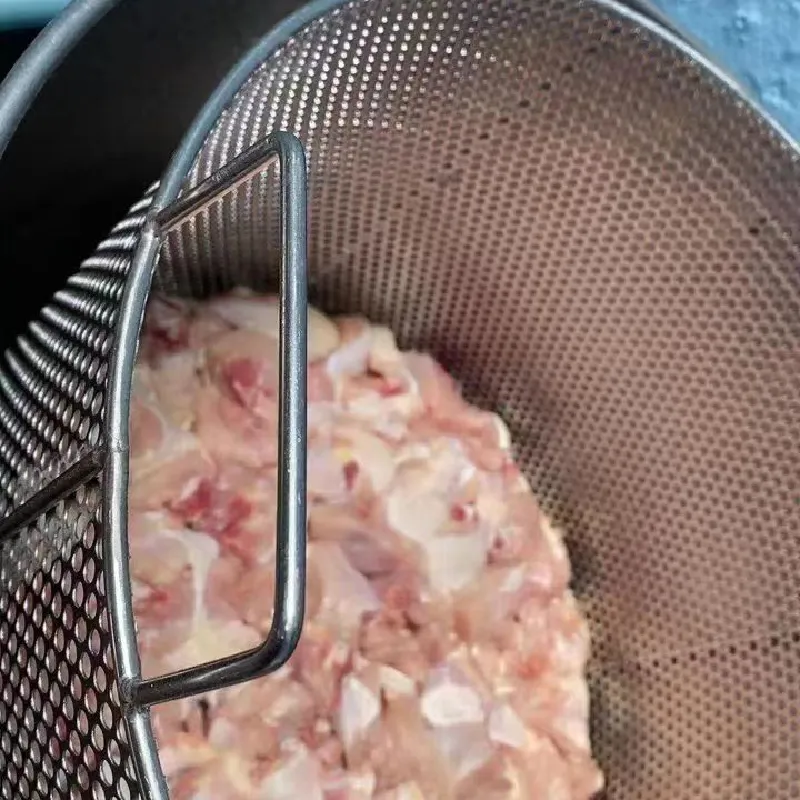

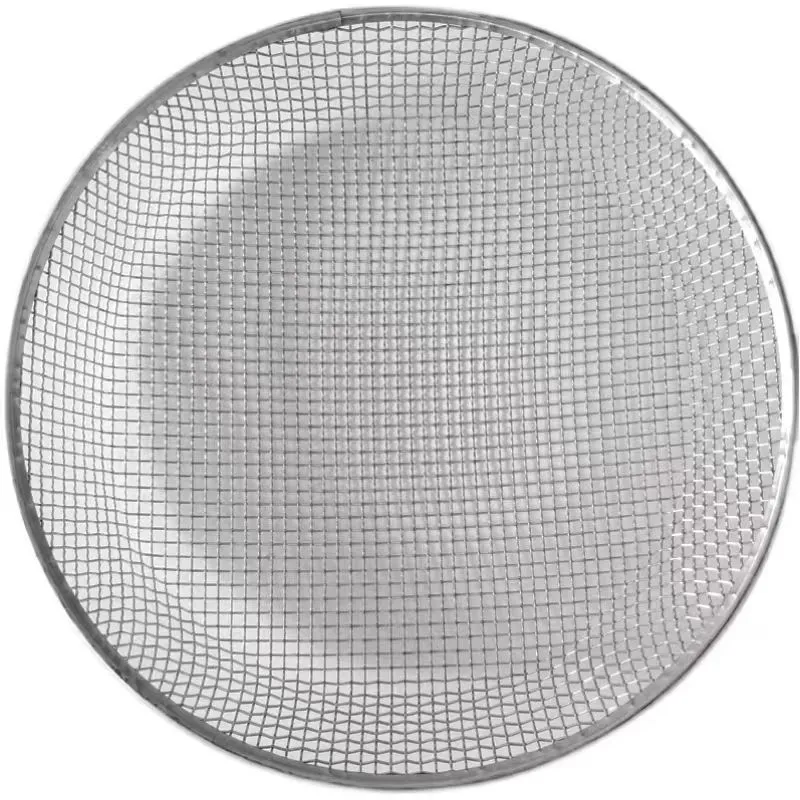

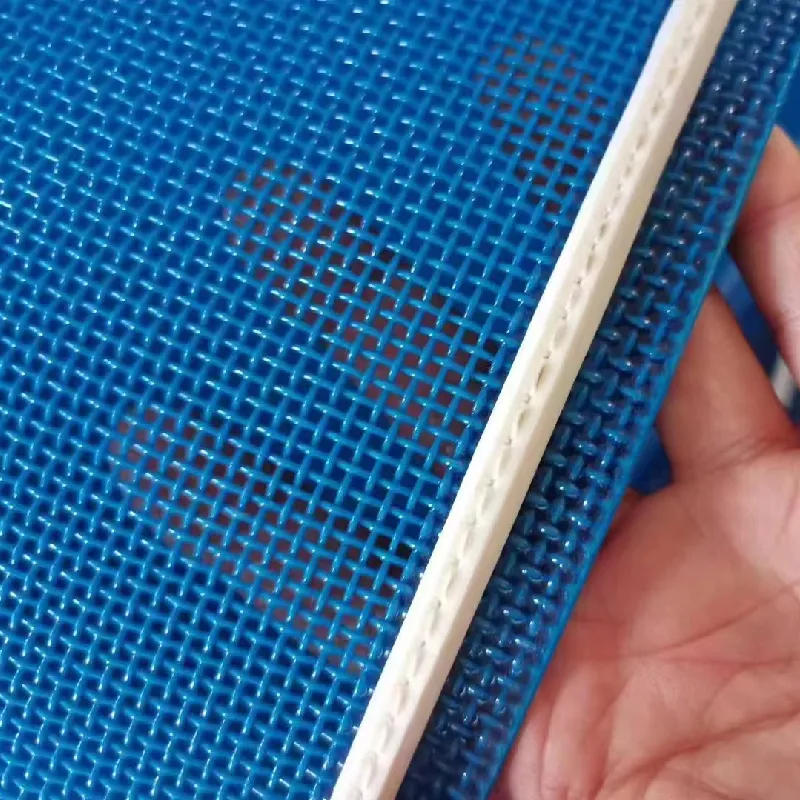

Filtraasje: Wire mesh filtration is a common filtration technology, mostly used for filtration of liquids, gases and other media. It uses the pores of the wire mesh to remove impurities in the medium to achieve the purpose of filtration. It is mostly used in wastewater treatment, food processing, pharmaceuticals, paints and coatings, etc.

Ofdruk: It is a technology that uses patterns or words on the screen to print ink or paint onto the printing material through pressure to form the desired pattern or words. It is characterized by good printing effect, low cost and simple operation. It is mostly used in textiles, electronic products, glass products, pharmaceutical packaging, etc.

Beskerming: Wire gaas shielding is in technology dy't brûkt de metalen conductivity fan de tried gaas te beskermjen elektromagnetyske weagen binnen de tried gaas te berikken shielding doelen. It wurdt meast brûkt foar de normale wurking fan elektroanyske apparatuer, kommunikaasjeapparatuer, medyske apparatuer, en loftfeartapparatuer.

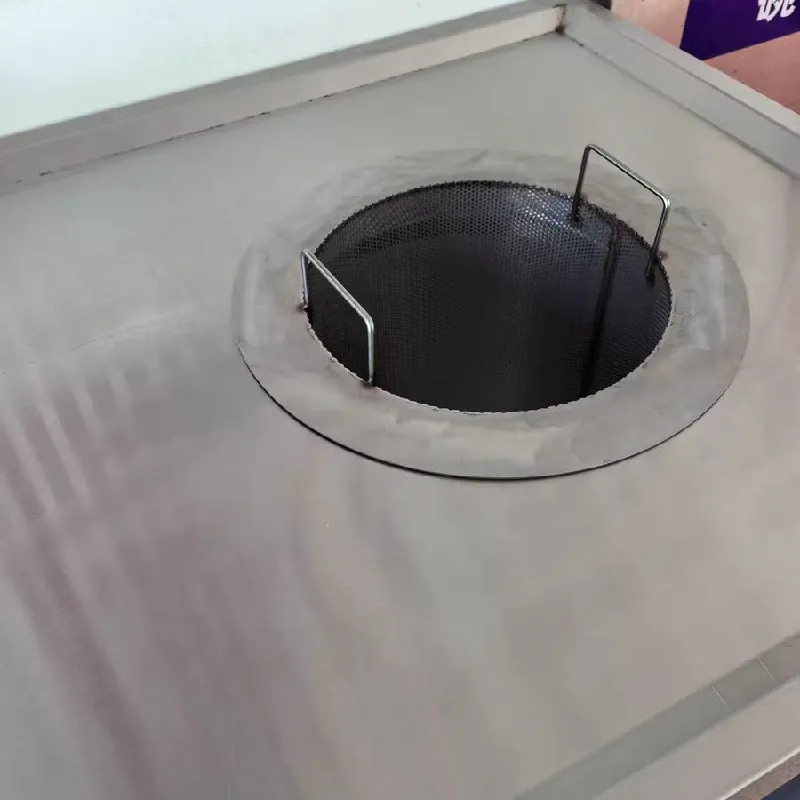

Choose stainless steel wire mesh, stainless steel mat mesh, copper wire mesh, stainless steel punched mesh, expanded steel mesh, and stainless steel filter mesh barrel.

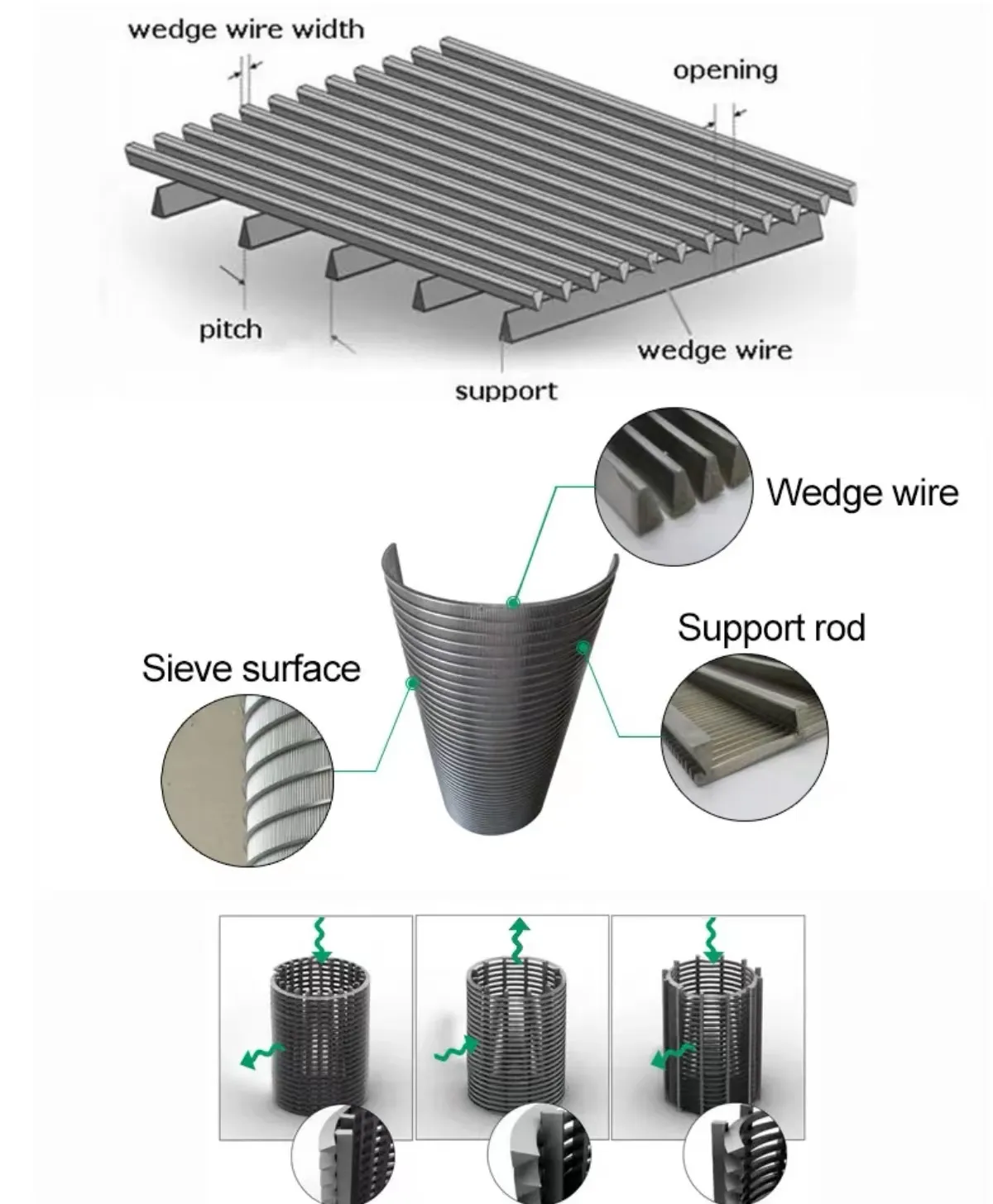

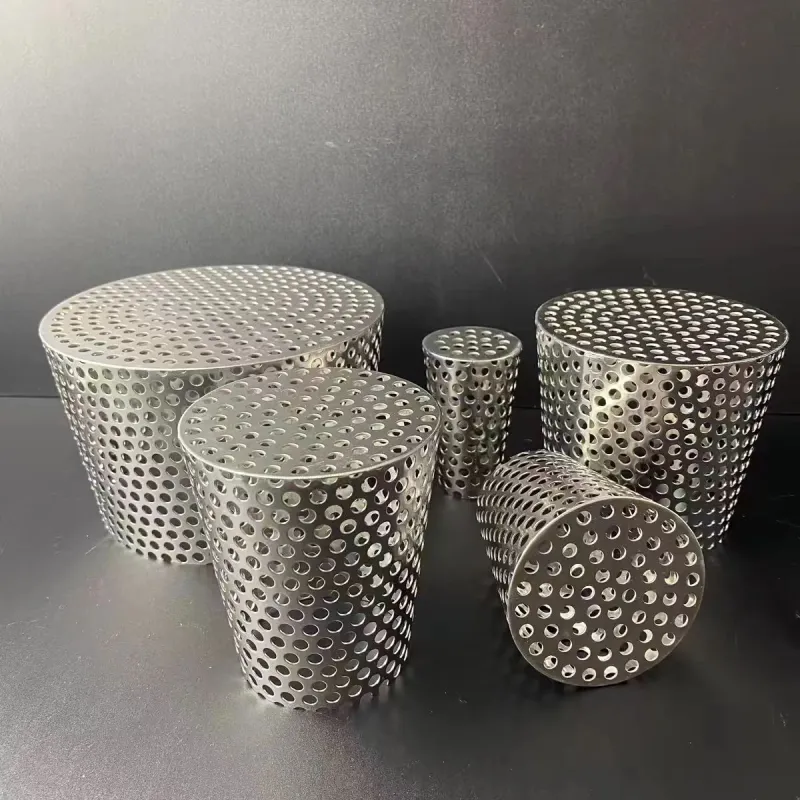

What types of filter cartridges are there?

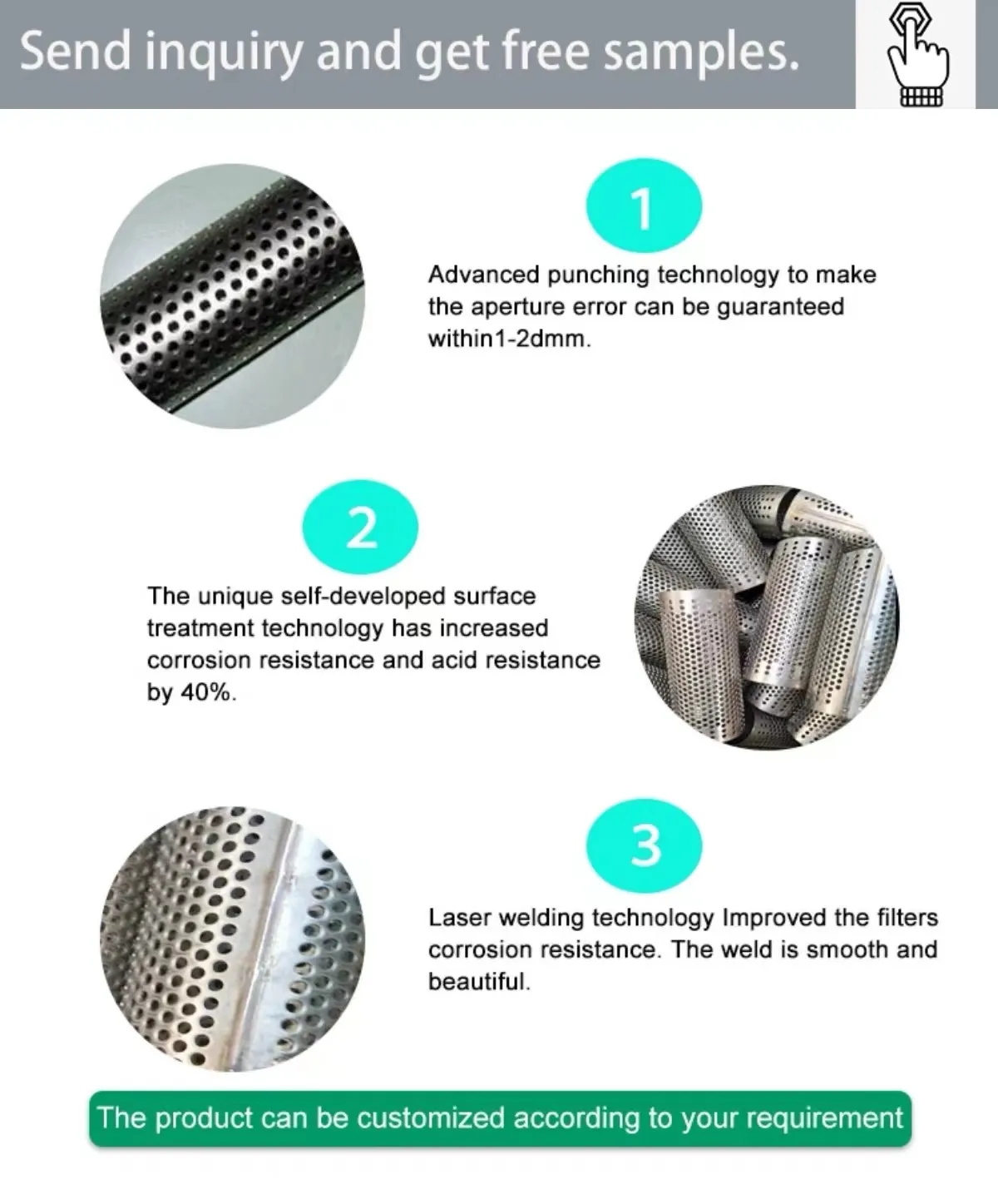

Stainless steel filter cylinder, punched mesh filter cylinder, stainless steel mat mesh cylinder, conical filter cylinder, cylindrical filter cylinder, edged filter cylinder, filter cylinder with handle, double or multi-layer filter cylinder, outer Braided mesh filter cylinder inside punched mesh, etched mesh filter cylinder, special-shaped filter cylinder, etc.

2. Wat binne de ôfmjittings fan de filter cartridge?

Because the needs of various industries are different, there are no unified specifications and sizes. All filter cartridges are customized according to customer requirements.

3. Hokker soarte fan welding proses wurdt brûkt foar de filter cartridge?

Brûk spot welding of folsleine welding, direkte welding of spiraal welding, of argon arc welding.

D'r binne in pear samples fan filterpatronen, mar troch ferskate gaasnûmers, struktueren en maten kinne de besteande samples faaks net foldwaan oan klanteasken. De besteande samples wurde allinich brûkt om te bewizen dat wy dit of dat soarte fan filterpatroan kinne produsearje (wolkom om te freegjen oer foto's)