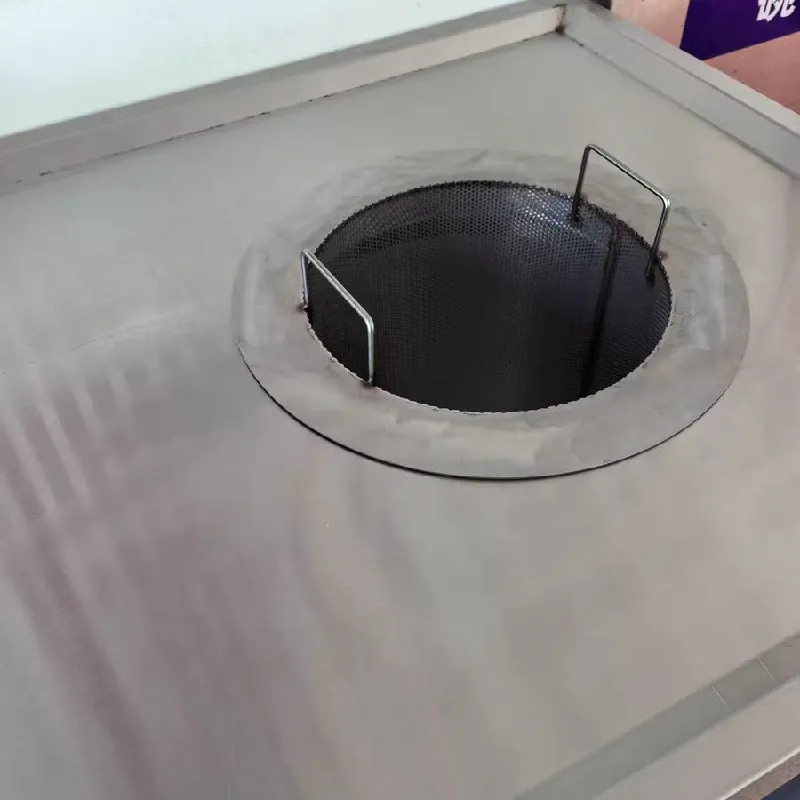

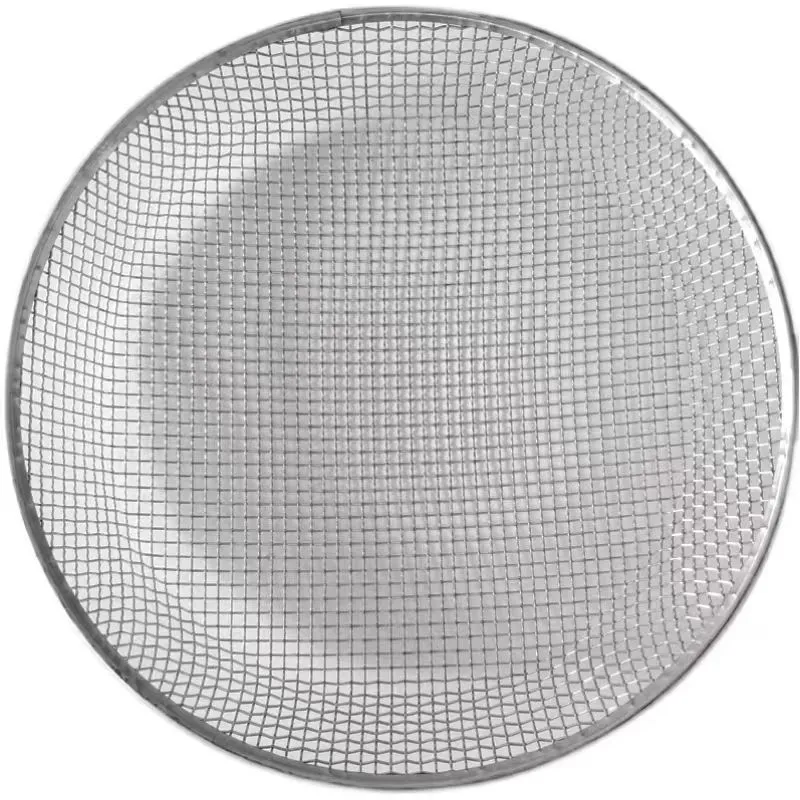

Screening: Screening refers to the process of classifying substances by separating different sizes or shapes using various technologies such as vibrating screens, trommel screens or rotary screens. It is mostly used in metallurgy, petrochemical, automobile, plastics and other industries to screen solid particles and powders.

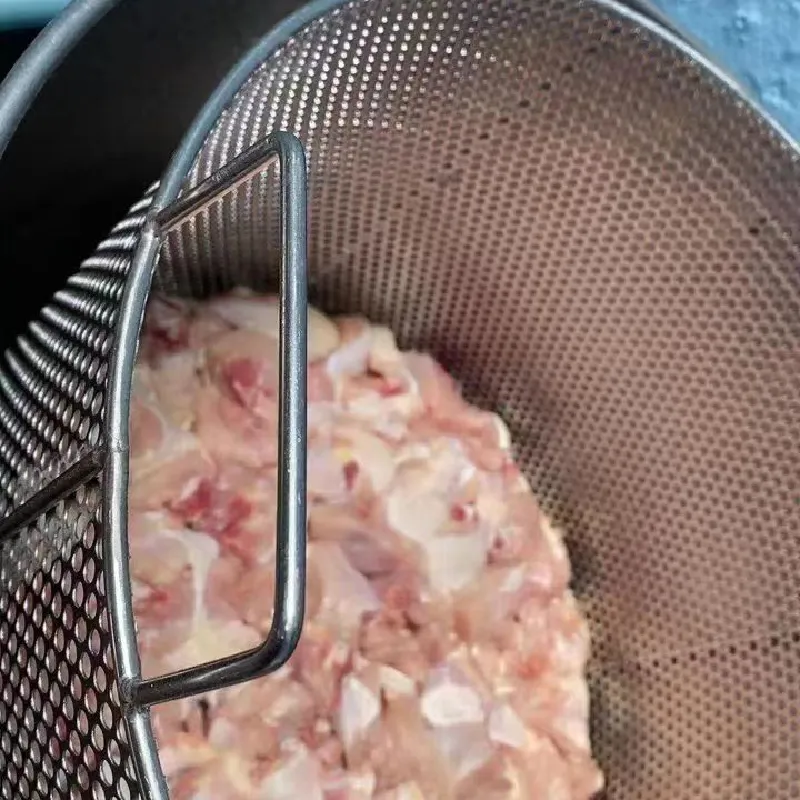

Filtrare: Wire mesh filtration is a common filtration technology, mostly used for filtration of liquids, gases and other media. It uses the pores of the wire mesh to remove impurities in the medium to achieve the purpose of filtration. It is mostly used in wastewater treatment, food processing, pharmaceuticals, paints and coatings, etc.

Imprimare: It is a technology that uses patterns or words on the screen to print ink or paint onto the printing material through pressure to form the desired pattern or words. It is characterized by good printing effect, low cost and simple operation. It is mostly used in textiles, electronic products, glass products, pharmaceutical packaging, etc.

Ecranare: Ecranarea cu plasă de sârmă este o tehnologie care utilizează conductivitatea metalică a plasei de sârmă pentru a proteja undele electromagnetice din interiorul plasei de sârmă pentru a atinge scopuri de ecranare. Este folosit mai ales pentru funcționarea normală a echipamentelor electronice, a echipamentelor de comunicații, a echipamentelor medicale și a echipamentelor de aviație.

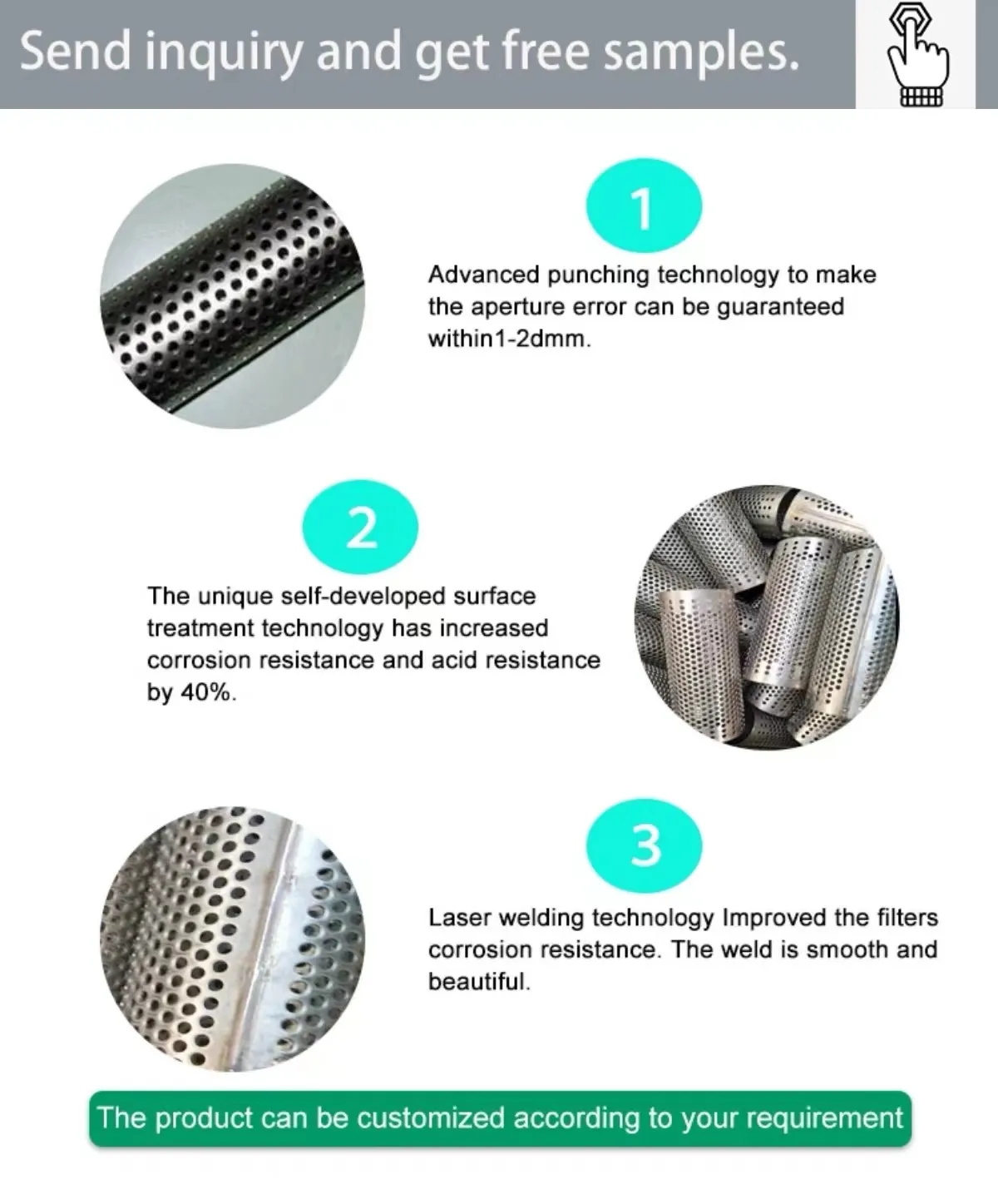

Choose stainless steel wire mesh, stainless steel mat mesh, copper wire mesh, stainless steel punched mesh, expanded steel mesh, and stainless steel filter mesh barrel.

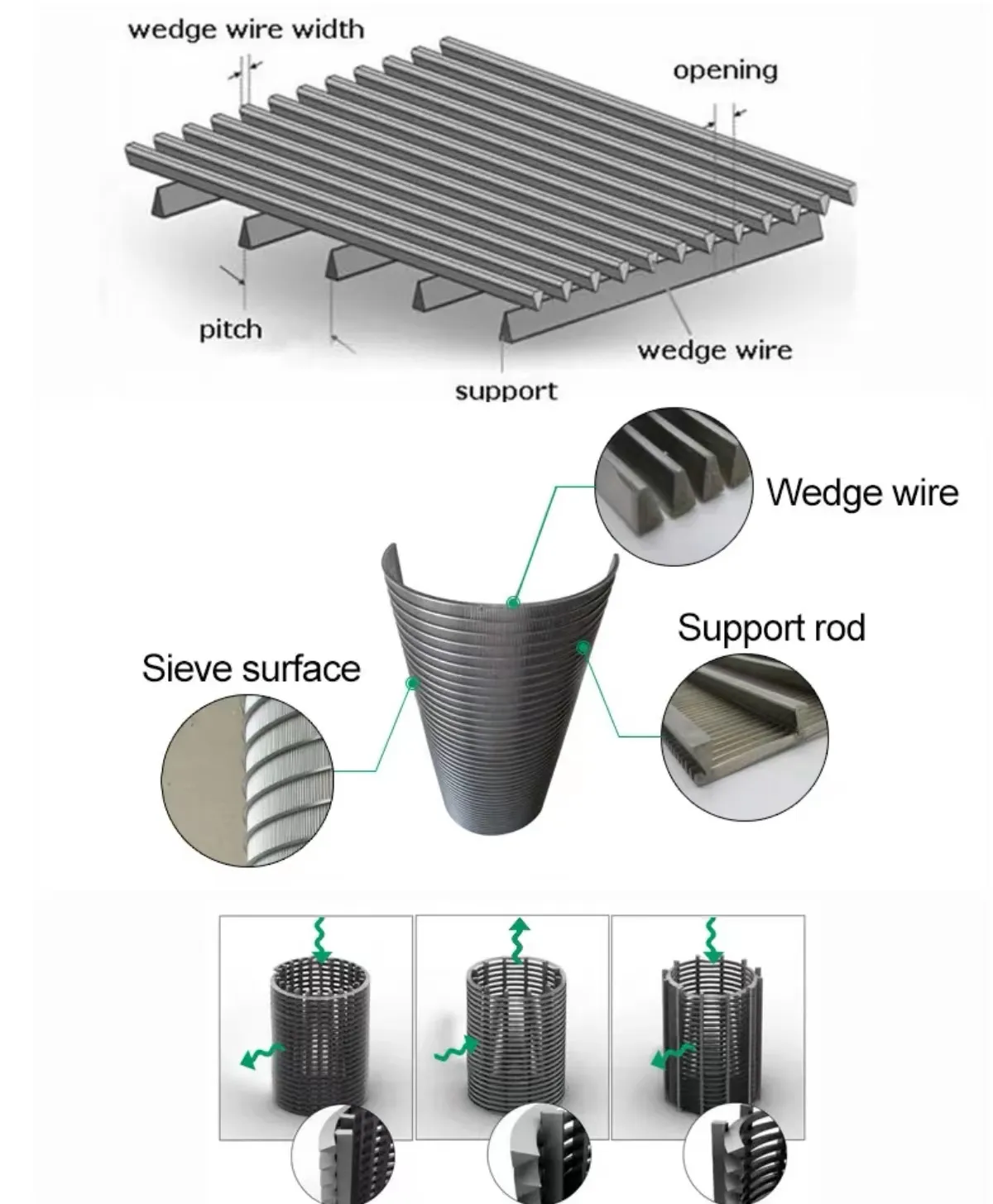

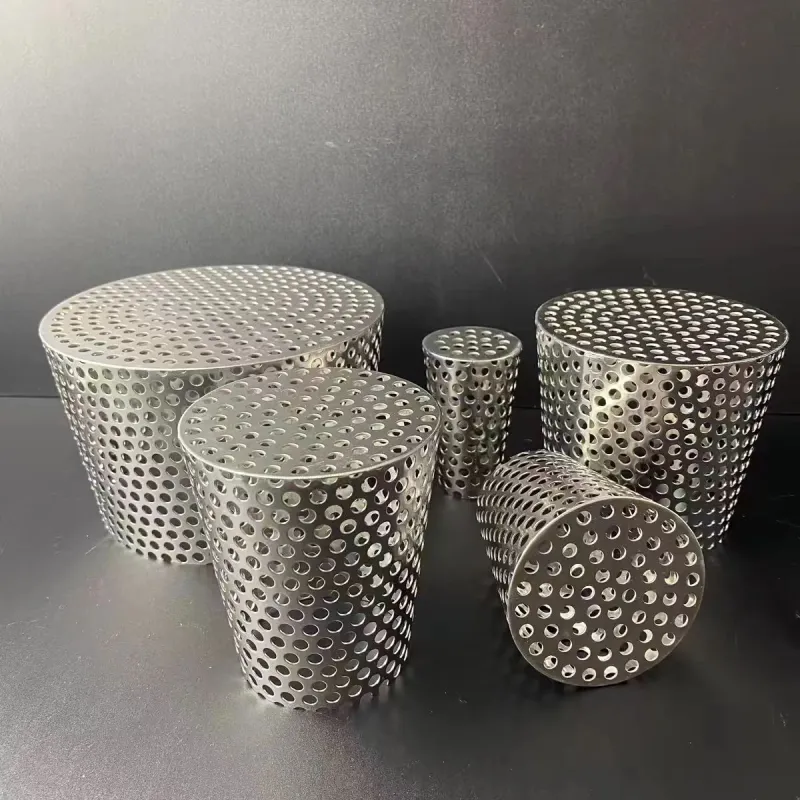

What types of filter cartridges are there?

Stainless steel filter cylinder, punched mesh filter cylinder, stainless steel mat mesh cylinder, conical filter cylinder, cylindrical filter cylinder, edged filter cylinder, filter cylinder with handle, double or multi-layer filter cylinder, outer Braided mesh filter cylinder inside punched mesh, etched mesh filter cylinder, special-shaped filter cylinder, etc.

2. Care sunt dimensiunile cartuşului filtrant?

Because the needs of various industries are different, there are no unified specifications and sizes. All filter cartridges are customized according to customer requirements.

3. Ce fel de proces de sudare este utilizat pentru cartuşul filtrant?

Utilizați sudarea în puncte sau sudarea completă, sudarea directă sau sudarea în spirală sau sudarea cu arc cu argon.

Există câteva mostre de cartușe de filtrare, dar din cauza diferitelor numere de plasă, structuri și dimensiuni, mostrele existente adesea nu pot satisface cerințele clienților. Mostrele existente sunt folosite doar pentru a dovedi că putem produce acest sau acel tip de cartuș filtrant (bine ați venit să întrebați despre imagini)