-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 21, 2025 03:58

Back to list

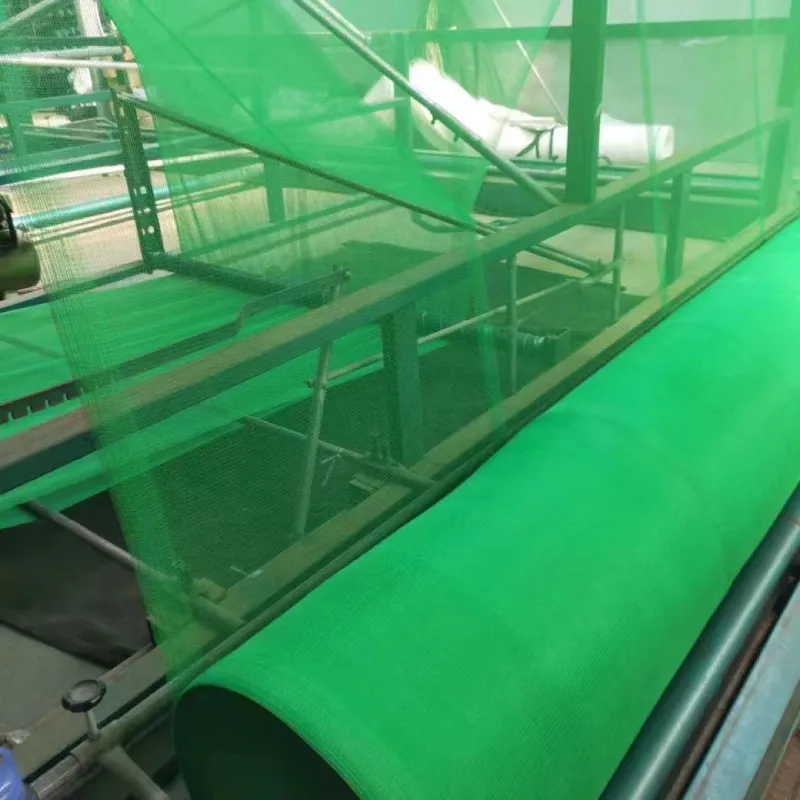

nylon mesh screen

In the modern industrial landscape, mining screen mesh stands out as a pivotal component that significantly enhances mining operations. These wire meshing products are integral to the separation and classification of materials extracted in the mining industry. Drawing from decades of field experience and supported by profound scientific principles, mining screen mesh is not only a technical necessity but also a cornerstone for efficient mining processes.

When evaluating the authoritativeness of mining screen mesh, it is crucial to consider the testimonials and case studies by industry professionals. Companies that have switched to well-designed screening systems report significant gains. For example, a coal mining firm in Australia upgraded its mesh screens, resulting in a 30% increase in throughput and a similar improvement in screening efficiency. Such outcomes underscore the transformative impact that a proper understanding and application of mining screen mesh can have on operational economics. Trustworthiness of suppliers is another critical aspect when investing in mining screen mesh. It is imperative to choose reputed manufacturers who assure quality standards and provide comprehensive after-sales support. The industry is rife with substandard products that can lead to frequent breakdowns and added maintenance costs. Genuine products not only fulfill statutory safety standards but are also backed by certifications from international quality assurance bodies. In-depth knowledge of these meshes extends beyond their physical use—it's embedded in an ethos of safety, environmental consciousness, and cost-effectiveness. Adopting state-of-the-art designs, meshes are crafted with eco-friendly materials that minimize environmental impact while enhancing the recyclability of components post-use. This sustainable approach propels companies towards a greener mining philosophy, aligning with global efforts to reduce industrial footprints. In conclusion, embracing cutting-edge mining screen mesh entails a multifaceted understanding of its materials, application scenarios, and compatibility with modern mining equipment. As operational demands grow, so does the necessity for reliable, efficient screening technologies. The future of mining rests not only on the capability of extracting resources but on refining them with precision and care, attributes epitomized by the strategic use of mining screen mesh. By integrating these sophisticated systems into their workflow, mining enterprises can not only improve their bottom line but also contribute to a more sustainable and innovative industrial paradigm.

When evaluating the authoritativeness of mining screen mesh, it is crucial to consider the testimonials and case studies by industry professionals. Companies that have switched to well-designed screening systems report significant gains. For example, a coal mining firm in Australia upgraded its mesh screens, resulting in a 30% increase in throughput and a similar improvement in screening efficiency. Such outcomes underscore the transformative impact that a proper understanding and application of mining screen mesh can have on operational economics. Trustworthiness of suppliers is another critical aspect when investing in mining screen mesh. It is imperative to choose reputed manufacturers who assure quality standards and provide comprehensive after-sales support. The industry is rife with substandard products that can lead to frequent breakdowns and added maintenance costs. Genuine products not only fulfill statutory safety standards but are also backed by certifications from international quality assurance bodies. In-depth knowledge of these meshes extends beyond their physical use—it's embedded in an ethos of safety, environmental consciousness, and cost-effectiveness. Adopting state-of-the-art designs, meshes are crafted with eco-friendly materials that minimize environmental impact while enhancing the recyclability of components post-use. This sustainable approach propels companies towards a greener mining philosophy, aligning with global efforts to reduce industrial footprints. In conclusion, embracing cutting-edge mining screen mesh entails a multifaceted understanding of its materials, application scenarios, and compatibility with modern mining equipment. As operational demands grow, so does the necessity for reliable, efficient screening technologies. The future of mining rests not only on the capability of extracting resources but on refining them with precision and care, attributes epitomized by the strategic use of mining screen mesh. By integrating these sophisticated systems into their workflow, mining enterprises can not only improve their bottom line but also contribute to a more sustainable and innovative industrial paradigm.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025